VPP

- VPP is a wire with the copper conductors, the polyethylene insulation and the sheath of light-stabilized polyethylene.

- It is used to distribute energy to a rated alternating voltage of 660 V with a frequency of 50 Hz for operation in a fixed position during long-term operation of water-submersible electric engines in the water of artesian wells under a pressure of 7.09*106

- It is used to connect devices that are located in the water (for example, submersible pumps in wells). The pressure that the wire can withstand allows it to be used not only in well houses, but also in artesian wells with a depth of more than 30 m. It can also be used in mines to pump out water from flooded longwalls.

- VPV wire (PVC compound sheath) differs from VPP wire (light-stabilized polyethylene sheath) in that it is less resistant to salt sea water, but more resistant to light.

operation: from -40°С tо +80°С

The copper conductor is not indicated on the marking;

V – submersible;

P – polyethylene insulation;

P – polyethylene sheath.

| Conductors: copper multi-wire (class 2 of the National Standards of Ukraine EN 60228) |

| Insulation: polyethylene |

| Armor: no |

| Number of conductors | Nominal cross-section area of the conductors, mm2 |

|---|---|

| 1 | 1,5 - 70 |

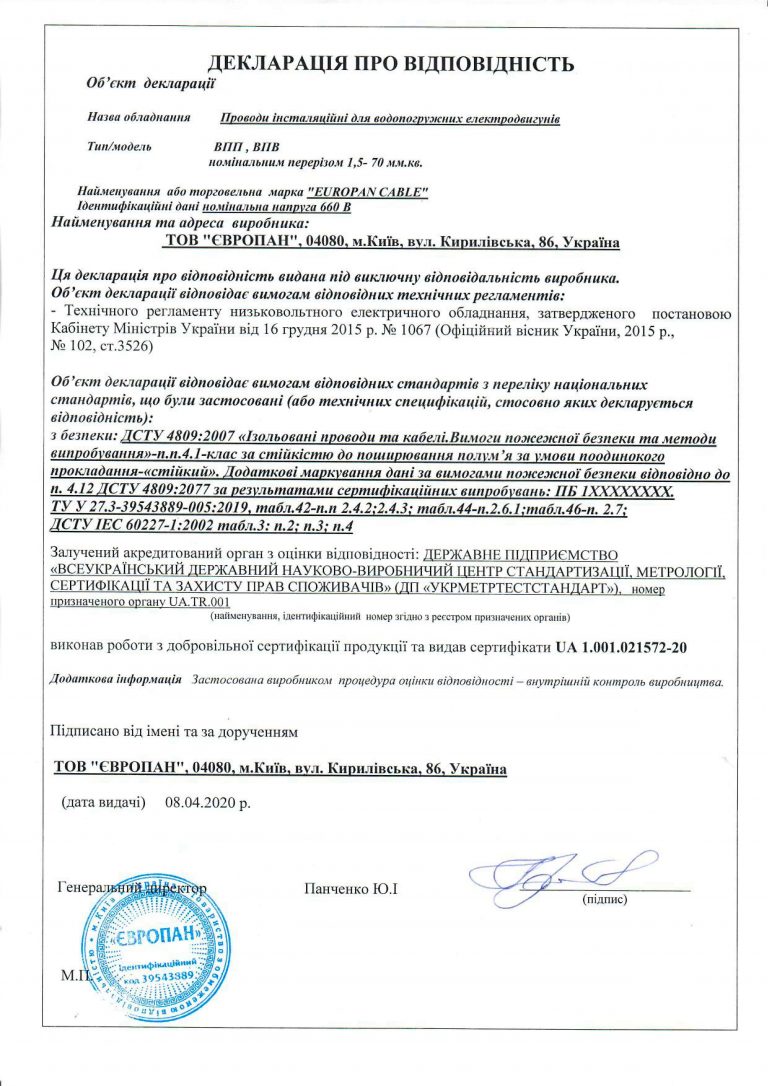

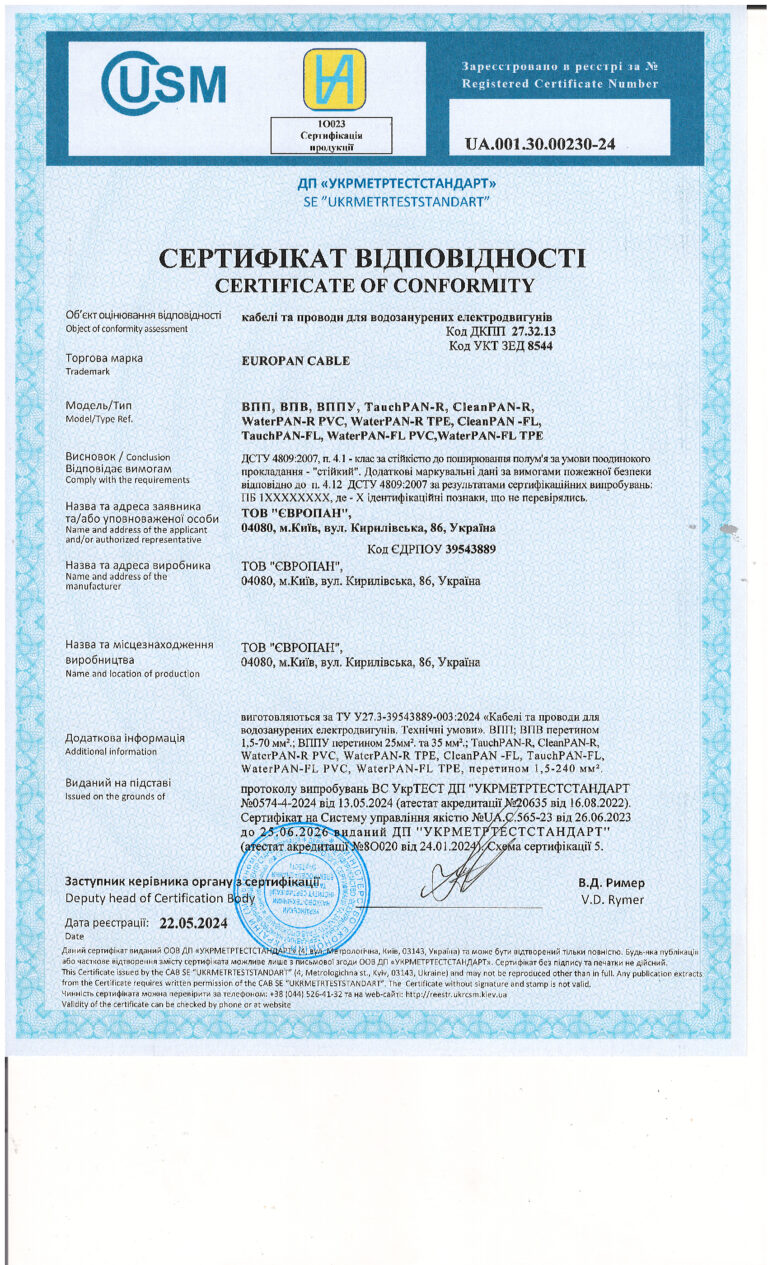

- The National Standards of Ukraine 4809:2007

- VPP - PB 1XXXXXXXX

VPP is a wire with the copper conductors, the polyethylene insulation, and the sheath of light-stabilized polyethylene. It belongs to a special type of so-called submersible wires that pump water out of wells, are resistant to mechanical damage and able to withstand the adverse effects of water.

Application scope

The submersible wire VPP is used to connect devices located and operating for a long time in the water. They help to connect water-submersible electric motors and pumps in the water of artesian wells under a pressure of 7.09 * 106 Pa, in well houses, rivers, pools, various reservoirs and mines. It can also be used for laying networks of drinking water sources and fountains, in drainage systems, in the construction of dams and weirs. It is also used to connect drilling equipment and electrical mechanisms operating at quays or seaports.

VPP is used only for the fixed connection of mechanisms for a rated alternating voltage of 660 V with a frequency of 50 Hz.

Design

The VPP design is based on a copper conductor, stranded from several thin wires of the 2nd flexibility class (class 2 of the National Standards of Ukraine EN 60288). The cross-sectional area of the conductor varies from 1.5 to 70 mm2. The insulation of the conductors and the outer sheath of the wire are made of polyethylene.

The polyethylene in VPP performs two important functions at once. It protects the conductor from the contact with water, and also serves as a protection against mechanical damage. The material is characterized by increased ductility and tear resistance.

The internal and external polyethylene insulation made the wire more flexible, increasing its resistance to the tension strain, and the ingress of oils and diesel fuel.

Operation

VPP is resistant to extremely high and fairly low temperatures. It is used at ambient temperatures from -40°C to +80°C. Wire installation is allowed at a temperature not lower than -15°С. Otherwise, the product must be preheated.

The minimum bend radius during installation is 10 outer wire diameters.

The long-term permissible heating temperature of the wire conductor during operation is +70°С.

The service life is at least 6 years. The guaranteed service life is 2 years.

The website of EUROPAN LLC presents VPP and VPV submersible wires of various label sizes. They are very different and differ from each other in the shape, cross-section and power. In order for the choice to be made correctly, first of all, you need to correctly determine the required diameter. The higher the power, the thicker the product should be. If you need help choosing a wire, our managers are ready to advise you and choose the best solution based on your technical requirements. They regularly improve their qualifications, which helps to give the most competent and detailed answers to even the most difficult questions of the client.

All our products are certified in accordance with the Ukrainian legislation and meet high safety requirements. Due to the fact that our company is a direct manufacturer, we offer our customers the best price-quality ratio.

Select rated voltage, kV

|

Nominal cross-section of the conductor, mm2 |

Outer diameter, mm |

Estimated weight of 1 km of wire, kg |

| 1,5 | 5,4 | 34 |

| 2,5 | 6,0 | 48 |

| 4,0 | 6,6 | 64 |

| 6,0 | 7,1 | 83 |

| 10 | 9,1 | 142 |

| 16 | 10,0 | 199 |

| 25 | 11,7 | 298 |

| 35 | 12,9 | 395 |

| 50 | 14,8 | 541 |

| 70 | 16,4 | 724 |