Wires for overhead power lines

Overhead power lines are the most cost-effective way to transmit electricity over long distances. They are capable of conducting voltages of 110 kV and higher and provide electricity to remote regions with minimal losses. Most often, we may find overhead lines in rural areas and open spaces.

In modern electrical networks, more than 90% of overhead power lines are made using not insulated wires located in the open air and fixed on supports or other engineering structures. Such “bare” wires are constantly exposed to weather, which determines their structure features. The wires design is intended to ensure high electrical conductivity, mechanical and corrosion resistance, as well as cost-effectiveness. When choosing the material of execution and the type of structural elements, one should take into account the air temperature, the intensity of ice formation, and the rush of the wind. Materials such as copper, aluminum, and its alloys, as well as steel, to some extent, meet these requirements.

Copper has the best electrophysical and mechanical properties. However, it is a scarce material, therefore its use for overhead lines requires a special feasibility study. For this reason, copper wires are used in those overhead lines requiring high electrical conductivity and extra high corrosion resistance.

Aluminum is the key conductive material now. It is more common in nature, but at the same time, it is notable for its low strength. In this regard, aluminum wires are usually used for overhead lines with small spans between supports and for local distribution networks.

Steel is often used to enhance the mechanical strength of aluminum. Such wires are called steel-aluminum. They are made with a core of galvanized steel wires. This core, in its turn, is surrounded, in way of concentric circles, with a layer of aluminum wires. The main mechanical load is borne by the steel core, while the outer aluminum layer provides high electrical conductivity.

Steel has the best physical and mechanical properties. It is durable, but at the same time, it is highly corrosive, which does not allow the use of steel wires without special treatment. To prevent these processes, steel wires are galvanized. Steel wires are used to provide ultra-high mechanical strength for overhead lines and large spans such as water crossings. Bare wires for overhead power lines may be solid and multi-wire, consisting of one or two different metals, the so-called bimetallic and composite wires.

Solid wires are usually made of copper or steel. Composite wires are stranded from wires made of different metals. Bimetallic wires consist of a steel core covered with a layer of copper or aluminum. And multi-wires are made by stranding individual wires in a specific order. As a rule, the wire has a central conductor covered with layers of wires of the same diameter, made in opposite directions. Along with that, to avoid unwinding the wire, the wires of the external layer are always stranded to the right.

Multi-wires are more reliable since a break in one wire does not lead to a sharp decrease in its overall mechanical strength. They are more flexible for ease of installation and better resist vibration than solid wires.

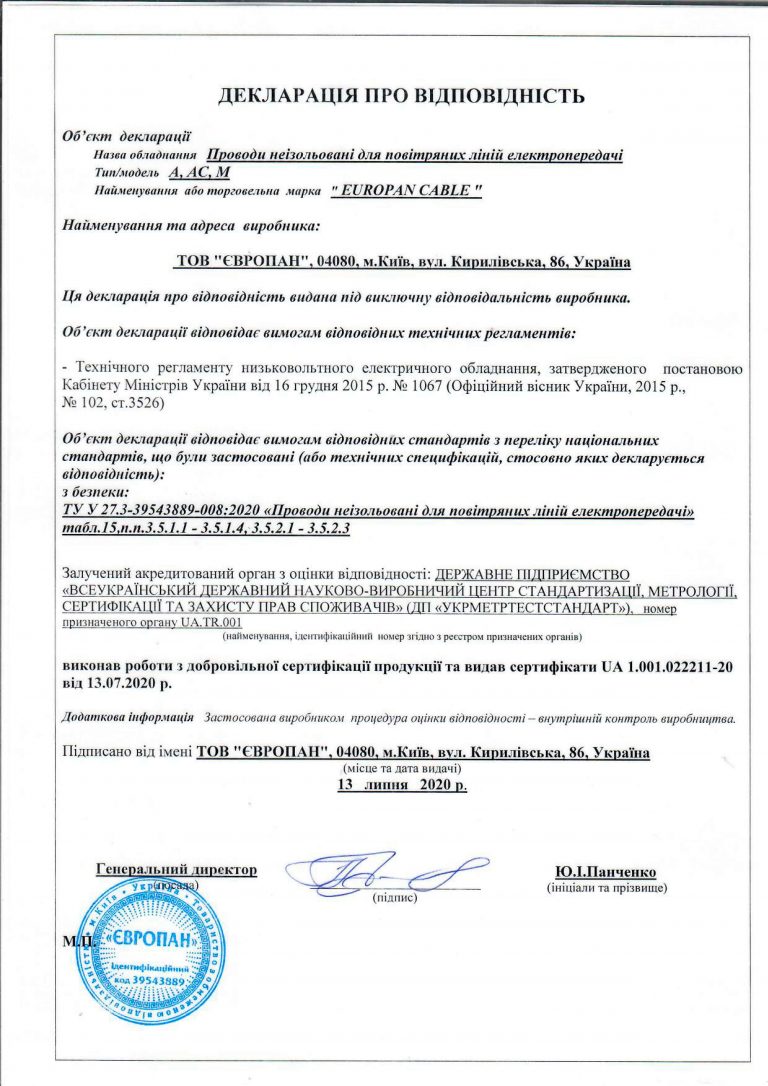

Wire marking for overhead lines consists of a code of letters and numbers. The letters denote the material from which the wire is made, and the numerical code denotes its nominal cross-section. The most common types of bare wires are:

M – copper wire;

A – aluminum wire;

AS steel-aluminum wire;

PS – steel multiconductor wire;

PSO – steel solid conductor.

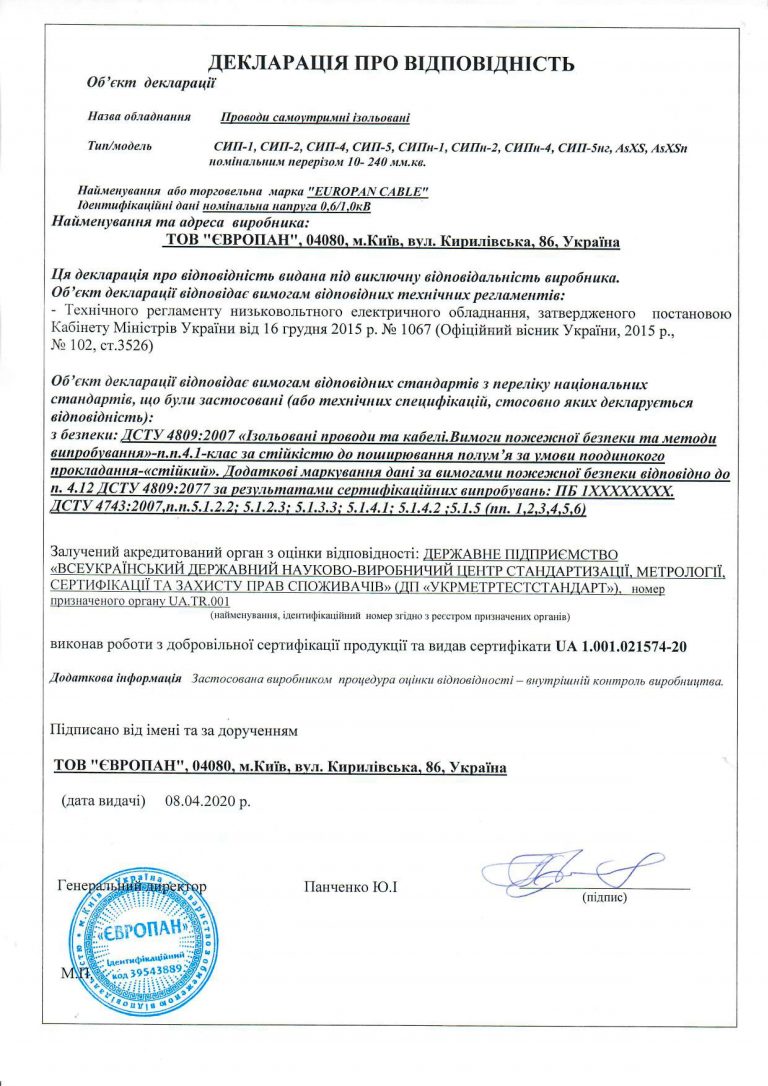

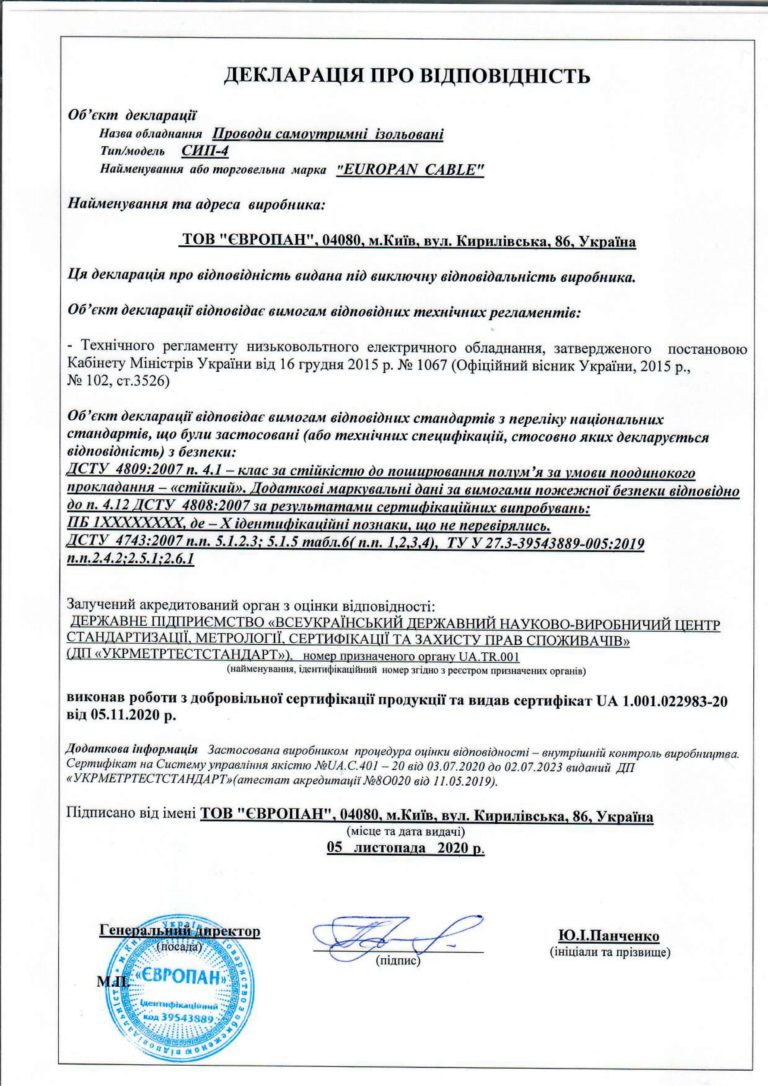

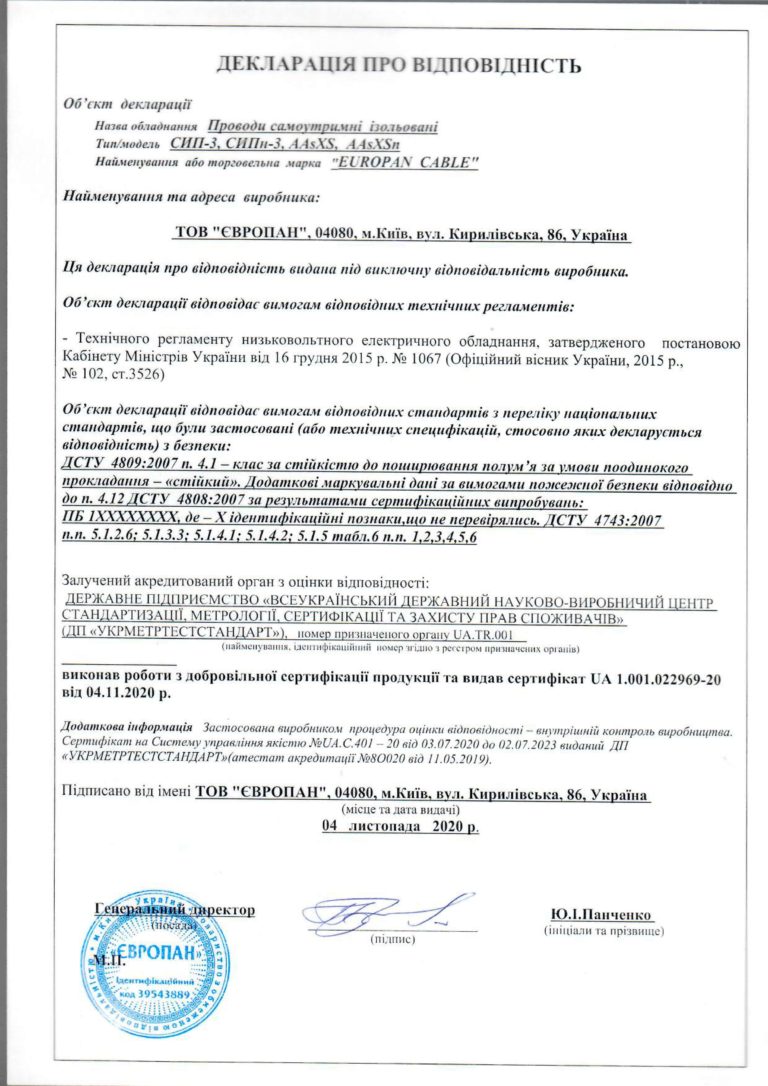

Recently, self-supporting insulated wires (SIP) have been widely used in the construction of overhead power lines. They are the wires stranded into a bundle and insulated with the light-stabilized polyethylene. The latter ones have 5 types of design, but all of them are insulated and have the same material of conductors. SIP conductors are always made of aluminum or alloy and are never copper.

SIP-1; SIP-2; SIP-4 and SIP-5 are designed for a voltage of 0.6 / 1.0 kV, with a frequency of 50Hz. And they are intended for the transmission of electricians through overhead lines and their further distribution. And SIP-3 is used for the installation of high voltage power lines for networks from 10 to 35 kV. It is always solid, consists of a wire-wound steel core.

SIP wires are resistant to ultraviolet light, freezing, and mechanical damage. They provide uninterrupted power supply even in difficult climatic and aggressive chemical conditions. They withstand up to + 250 ° С during a short circuit, can regain their shape after deformation, and due to the absence of the risk of electric shock when touching the phase wires, they are also safe for people, service personnel, as well as birds and animals. SIP is suitable for external vertical and horizontal wiring, installation on the walls of various structures, and laying on electricity to private houses and outbuildings. Today they are the best solution for industrial and residential applications, for connecting new and replacing existing networks. In comparison with bare wires, the reliability and safety of such lines increase to the level of cable ones, and the correct selection of conductors and several important advantages make their use economically viable.

EUROPAN Cable Plant produces copper, aluminum and steel-aluminum bare wires of M, A, AC types, as well as self-supporting wires SIP, АsXS, АsXSn of high quality for the equipment of central and distribution overhead power lines. Our products are characterized by high electrical conductivity, durability, corrosion resistance and when properly selected provide an economical design.