APvPg, APvPGng-HF

- APvPG is a power cable with the aluminum conductors, the insulation made of the cross-linked polyethylene and the light-stabilized polyethylene sheath.

- APvPGng-HF is a power cable with the aluminum conductors, the insulation made of the cross-linked polyethylene and halogen-free sheath, flame-retardant with the low smoke and gas emission.

- They are designed for the transmission and distribution of electricity in stationary installations for a rated alternating voltage of 1 kV and a frequency of 50 Hz.

- APvPG is used for laying in cable structures, industrial premises, on specialized cable tray systems, channels, cable cellars, mines, collectors. If there is no risk of mechanical damage, overhead installation is allowed. It is not recommended for laying in the earth trenches, but if such a laying is necessary, mechanical protection should be used.

- APvPGng-HF cables are used for stationary installation in offices and industrial premises, places of high concentration of computer and other microprocessor equipment, subway structures, residential and public buildings, as well as other places with higher fire safety requirements.

Multi conductor cable: 7.5 x outer diameter

operation: from -50°С to +50°С

A – the conductor is made of aluminum;

Pv – the insulation is made of cross-linked polyethylene;

P – the light-stabilized polyethylene sheath;

Png-HF – the halogen-free sheath;

G – no armor.

| Conductors: aluminum solid or multi wire of the 1st or 2d flexibility class (class 1 and 2 DSTU EN 60228) |

| Insulation: conductors’ insulation is made of cross-linked polyethylene, the sheath of APvPG is made of the light-stabilized polyethylene; APvPGng-HF has halogen-free sheath |

| Armor: no |

| Number of conductors | Nominal cross-section area of the key conductors, mm2 |

|---|---|

| 1 | 2,5 — 1000 |

| 2, 3, 4 | 2,5 — 300 |

| 5 | 2,5 — 240 |

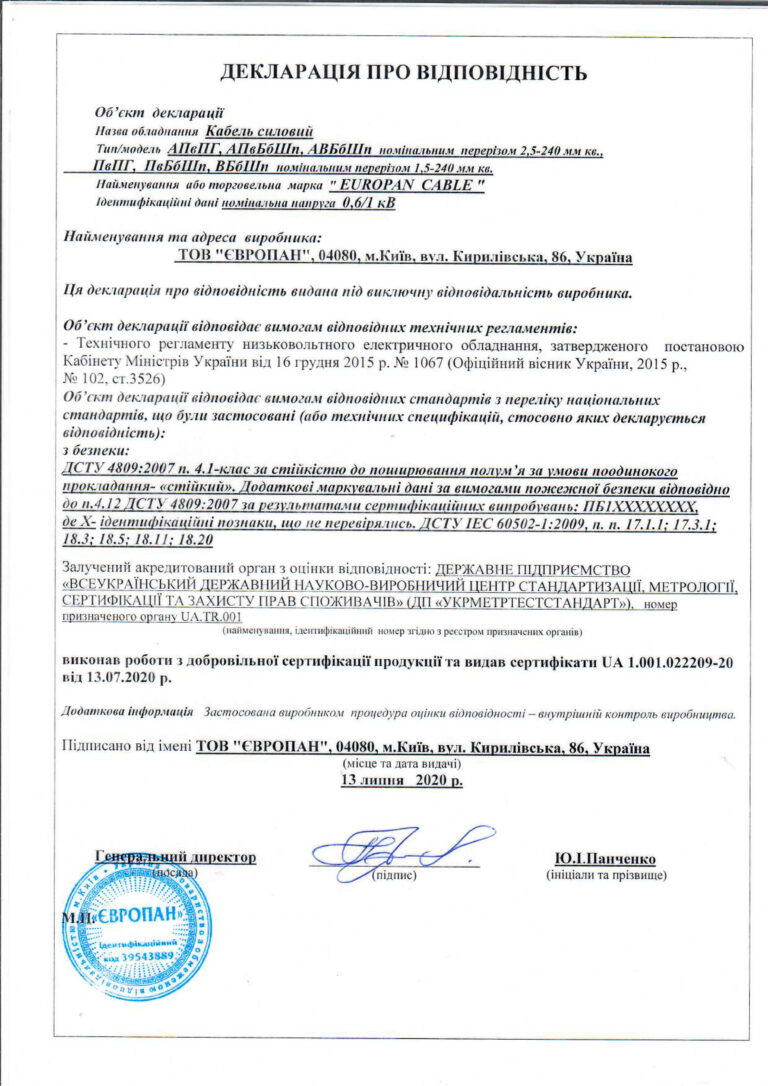

- The National Standards of Ukraine 4809:2007

- APvPG - PB 1XXXXXXXX

- APvPGng-HF - PB 122222XXX

APvPG belongs to the power cables the with aluminum conductors, the insulation made of the cross-linked polyethylene and the light-stabilized polyethylene sheath.

APvPGng-HF is a power cable with the aluminum conductors, the insulation made of the cross-linked polyethylene and the halogen-free sheath.

They are designed for transmission and distribution of electricity in stationary installations for a rated alternating voltage of 1 kV and a frequency of 50 Hz.

Applicability scope

APvPG is used for the single stationary laying in cable structures, industrial premises, on specialized cable tray systems, channels, cable cellars, mines and collectors. The use of polyethylene made the cable lighter and more flexible, which made it possible to use it for laying on difficult routes. Also, the insulation made of cross-linked polyethylene (XLPE) provided the cable with the high carrying capacity and minimized dielectric absorption loss. If there is no risk of mechanical damage, APvPG can be used for the overhead laying. This cable is not recommended to be laid in the ground, in trenches, the laying is allowed only with the use of protection against mechanical damage.

APvPGng-HF cables are fire-resistant during short circuits and when exposed to external sources of flame. They are characterized by the low toxicity, do not spread combustion when laid in bundles with the reduced smoke generation and the corroding agents emission. They are used in almost all public buildings, subway buildings, hospital departments, office premises, industrial buildings, residential buildings and other facilities with higher fire safety requirements.

Design

The design of the cables is based on a single-wire or multi-wire compacted round aluminum conductor (class 1, 2 DSTU EN 60228). The conductor insulation is made of cross-linked polyethylene (XLPE). The outer sheath of APvPG is made of light-stabilized polyethylene, while APvPGng-HF one is made of a polymer compound that does not contain halogens, practically does not emit smoke when ignited and does not emit carbon monoxide, fluorides, chlorides and other harmful compounds.

You can get more detailed information on the design features and technical parameters of the cables from the specialists of EUROPAN LLC by calling the phones indicated on the website. We will advise you on any issues related to cable products and help you in selecting a product.

Operation

Normal operation of cables is carried out in a stationary state at temperatures ranging from -50°C to +50°C. The installation is permissible at a temperature not lower than -15°C, otherwise the cable must be preheated. The maximum permissible air humidity at which the cable remains efficient is 98% at a temperature of + 35°С.

The minimum bend radius during installation for a single-conductor cable is at least 10 outer cable diameters, for a multi conductor cable – at least 7.5 outer cable diameters.

The maximum long-term permissible heating of the wires during operation should not exceed 90°C, during a short circuit – 250°C, in an emergency mode – no more than 130°C for 8 hours.

When properly installed and operated, the service life of the cables is at least 30 years from the date of manufacture. The guaranteed service life is 5 years.

On the website of EUROPAN LLC, you can select and buy in bulk aluminum and copper cables of the specified brand from stock, and custom-built, both meeting all international quality standards and certified in accordance with the Ukrainian legislation. Our managers will advise you on all issues and offer the most favorable terms for the supply of the required products.

Permissible short circuit currents of cables

|

Nominal conductor cross-section, mm² |

Permissible current of one-second short circuit of cables, kA |

Nominal conductor cross-section, mm² |

Permissible current of one-second short circuit of cables, kA |

| 2,5 | 0,22 | 120 | 10,71 |

| 4,0 | 0,36 | 150 | 13,16 |

| 6,0 | 0,52 | 185 | 16,53 |

| 10 | 0,87 | 200 | 21,70 |

| 16 | 1,40 | 300 | 27,12 |

| 25 | 2,24 | 400 | 36,16 |

| 35 | 3,09 | 500 | 45,20 |

| 50 | 4,18 | 625 | 59,95 |

| 70 | 6,12 | 800 | 72,33 |

| 95 | 8,48 | 1000 | 90,40 |

Select rated voltage, kV

|

Number of conductors and nominal cross-section, mm2 |

Nominal outer diameter, mm |

Estimated weight of 1 km of cables, kg |

| 1 x 2,5 | 5,6 | 28 |

| 1 x 4,0 | 6,1 | 35 |

| 1 x 6,0 | 6,6 | 43 |

| 1 x 10 | 7,4 | 59 |

| 1 x 16 | 9,5 | 95 |

| 1 x 25 | 11,2 | 136 |

| 1 x 35 | 12,4 | 171 |

| 1 x 50 | 14,1 | 228 |

| 1 x 70 | 15,2 | 292 |

| 1 x 95 | 16,9 | 377 |

| 1 x 120 | 18,9 | 470 |

| 1 x 150 | 20,8 | 576 |

| 1 x 185 | 23,0 | 710 |

| 1 x 240 | 25,9 | 910 |

| 1 x 300 | 28,2 | 1106 |

| 1 x 400 | 31,9 | 1442 |

| 1 x 500 | 35,5 | 1795 |

| 1 x 625 | 39,1 | 2205 |

| 1 x 800 | 43,4 | 2766 |

| 1 x 1000 | 48,2 | 3432 |

| 2 x 2,5 | 9,4 | 61 |

| 2 x 4,0 | 10,3 | 75 |

| 2 x 6,0 | 11,4 | 93 |

| 2 x 10 | 12,9 | 125 |

| 2 x 16 | 16,0 | 184 |

| 2 x 25 | 19,8 | 279 |

| 2 x 35 | 22,1 | 353 |

| 2 x 50 | 26,0 | 487 |

| 2 x 70 | 28,2 | 619 |

| 2 x 95 | 31,6 | 796 |

| 2 x 120 | 35,2 | 987 |

| 2 x 150 | 39,0 | 1206 |

| 2 x 185 | 43,3 | 1485 |

| 2 x 240 | 48,7 | 1896 |

| 2 x 300 | 53,4 | 2300 |

| 3 x 2,5 | 9,9 | 75 |

| 3 x 4,0 | 10,9 | 94 |

| 3 x 6,0 | 12,0 | 120 |

| 3 x 10 | 13,7 | 165 |

| 3 x 16 | 17,0 | 247 |

| 3 x 25 | 21,1 | 378 |

| 3 x 35 | 23,9 | 497 |

| 3 x 50 | 27,7 | 669 |

| 3 x 70 | 30,0 | 862 |

| 3 x 95 | 33,7 | 1119 |

| 3 x 120 | 37,5 | 1389 |

| 3 x 150 | 41,6 | 1707 |

| 3 x 185 | 46,6 | 2141 |

| 3 x 240 | 52,0 | 2702 |

| 3 x 300 | 57,4 | 3329 |

| 3 x 4,0 + 1 x 2,5 | 11,8 | 111 |

| 3 x 6,0 + 1 x 4,0 | 13,1 | 142 |

| 3 x 10 + 1 x 6,0 | 15,0 | 194 |

| 3 x 16 + 1 x 10 | 18,5 | 299 |

| 3 x 25 + 1 x 16 | 23,2 | 447 |

| 3 x 35 + 1 x 16 | 24,7 | 559 |

| 3 x 50 + 1 x 25 | 29,5 | 771 |

| 3 x 70 + 1 x 35 | 31,9 | 996 |

| 3 x 95 + 1 x 50 | 36,3 | 1326 |

| 3 x 120 + 1 x 70 | 40,0 | 1637 |

| 3 x 150 + 1 x 70 | 44,7 | 1984 |

| 3 x 185 + 1 x 95 | 49,7 | 2474 |

| 3 x 240 + 1 x 120 | 55,9 | 3148 |

| 3 x 300 + 1 x 150 | 61,3 | 3842 |

| 4 x 2,5 | 10,7 | 91 |

| 4 x 4,0 | 11,8 | 116 |

| 4 x 6,0 | 13,1 | 148 |

| 4 x 10 | 15,0 | 207 |

| 4 x 16 | 19,1 | 324 |

| 4 x 25 | 23,2 | 481 |

| 4 x 35 | 26,3 | 634 |

| 4 x 50 | 30,6 | 858 |

| 4 x 70 | 33,2 | 1113 |

| 4 x 95 | 37,7 | 1474 |

| 4 x 120 | 41,5 | 1801 |

| 4 x 150 | 46,5 | 2247 |

| 4 x 185 | 51,7 | 2786 |

| 4 x 240 | 58,1 | 3561 |

| 4 x 300 | 63,8 | 4346 |

| 5 x 2,5 | 11,6 | 111 |

| 5 x 4,0 | 12,9 | 143 |

| 5 x 6,0 | 14,3 | 184 |

| 5 x 10 | 16,4 | 259 |

| 5 x 16 | 21,0 | 409 |

| 5 x 25 | 26,0 | 626 |

| 5 x 35 | 29,0 | 805 |

| 5 x 50 | 34,2 | 1117 |

| 5 x 70 | 37,1 | 1445 |

| 5 x 95 | 41,7 | 1884 |

| 5 x 120 | 46,4 | 2336 |

| 5 x 150 | 51,5 | 2882 |

| 5 x 185 | 57,7 | 3616 |

| 5 x 240 | 64,5 | 4579 |

Select rated voltage, kV

|

Number of conductors and nominal cross-section, mm2 |

Nominal outer diameter, mm |

Estimated weight of 1 km of cables, kg |

| 1 x 2,5 | 5,6 | 39 |

| 1 x 4,0 | 6,0 | 46 |

| 1 x 6,0 | 6,6 | 56 |

| 1 x 10 | 7,4 | 73 |

| 1 x 16 | 9,5 | 119 |

| 1 x 25 | 11,2 | 165 |

| 1 x 35 | 12,4 | 204 |

| 1 x 50 | 14,1 | 266 |

| 1 x 70 | 15,2 | 333 |

| 1 x 95 | 16,9 | 423 |

| 1 x 120 | 18,9 | 529 |

| 1 x 150 | 20,8 | 641 |

| 1 x 185 | 22,9 | 783 |

| 1 x 240 | 25,8 | 1002 |

| 1 x 300 | 28,2 | 1207 |

| 1 x 400 | 31,8 | 1557 |

| 1 x 500 | 35,5 | 1937 |

| 1 x 625 | 39,0 | 2363 |

| 1 x 800 | 43,4 | 2942 |

| 1 x 1000 | 48,2 | 3647 |

| 2 x 2,5 | 11,4 | 172 |

| 2 x 4,0 | 12,3 | 204 |

| 2 x 6,0 | 13,5 | 251 |

| 2 x 10 | 15,1 | 319 |

| 2 x 16 | 18,8 | 488 |

| 2 x 25 | 22,2 | 680 |

| 2 x 35 | 25,1 | 875 |

| 2 x 50 | 28,6 | 1140 |

| 2 x 70 | 30,9 | 1386 |

| 2 x 95 | 35,0 | 1791 |

| 2 x 120 | 38,1 | 2137 |

| 2 x 150 | 42,1 | 2610 |

| 2 x 185 | 47,0 | 3252 |

| 2 x 240 | 52,2 | 4040 |

| 2 x 300 | 57,5 | 4924 |

| 3 x 2,5 | 11,8 | 184 |

| 3 x 4,0 | 13,0 | 227 |

| 3 x 6,0 | 14,1 | 272 |

| 3 x 10 | 15,8 | 349 |

| 3 x 16 | 19,8 | 533 |

| 3 x 25 | 24,0 | 785 |

| 3 x 35 | 26,5 | 964 |

| 3 x 50 | 30,5 | 1278 |

| 3 x 70 | 32,7 | 1554 |

| 3 x 95 | 37,1 | 2015 |

| 3 x 120 | 40,6 | 2435 |

| 3 x 150 | 45,1 | 2994 |

| 3 x 185 | 49,9 | 3674 |

| 3 x 240 | 55,9 | 4635 |

| 3 x 300 | 61,2 | 5589 |

| 3 x 4,0 + 1 x 2,5 | 14,0 | 256 |

| 3 x 6,0 + 1 x 4,0 | 15,2 | 308 |

| 3 x 10 + 1 x 6,0 | 17,1 | 399 |

| 3 x 16 + 1 x 10 | 20,8 | 579 |

| 3 x 25 + 1 x 16 | 25,3 | 850 |

| 3 x 35 + 1 x 16 | 27,2 | 987 |

| 3 x 50 + 1 x 25 | 32,2 | 1388 |

| 3 x 70 + 1 x 35 | 35,3 | 1741 |

| 3 x 95 + 1 x 50 | 39,3 | 2183 |

| 3 x 120 + 1 x 70 | 43,1 | 2664 |

| 3 x 150 + 1 x 70 | 48,1 | 3304 |

| 3 x 185 + 1 x 95 | 53,3 | 4064 |

| 3 x 240 + 1 x 120 | 59,6 | 5123 |

| 3 x 300 + 1 x 150 | 66,3 | 6341 |

| 4 x 2,5 | 12,9 | 214 |

| 4 x 4,0 | 14,0 | 256 |

| 4 x 6,0 | 15,2 | 309 |

| 4 x 10 | 17,1 | 401 |

| 4 x 16 | 21,5 | 614 |

| 4 x 25 | 26,1 | 908 |

| 4 x 35 | 28,9 | 1120 |

| 4 x 50 | 33,4 | 1490 |

| 4 x 70 | 36,5 | 1887 |

| 4 x 95 | 40,9 | 2402 |

| 4 x 120 | 45,1 | 2925 |

| 4 x 150 | 49,8 | 3573 |

| 4 x 185 | 55,6 | 4446 |

| 4 x 240 | 62,0 | 5577 |

| 4 x 300 | 68,9 | 6907 |

| 5 x 2,5 | 13,8 | 243 |

| 5 x 4,0 | 15,0 | 294 |

| 5 x 6,0 | 16,4 | 357 |

| 5 x 10 | 19,2 | 498 |

| 5 x 16 | 24,0 | 759 |

| 5 x 25 | 28,5 | 1071 |

| 5 x 35 | 31,8 | 1348 |

| 5 x 50 | 37,2 | 1836 |

| 5 x 70 | 40,2 | 2279 |

| 5 x 95 | 45,5 | 2954 |

| 5 x 120 | 49,7 | 3544 |

| 5 x 150 | 55,5 | 4392 |

| 5 x 185 | 61,7 | 5432 |

| 5 x 240 | 69,6 | 6955 |