APV, APVngd

- APV, APVngd are the wires with an aluminum conductor and PVC insulation.

- They are designed for electrical installations with stationary laying in lighting and power networks, as well as for the installation of electrical equipment, machines, mechanisms and machine tools for a rated voltage of up to 450 V (for networks up to 450/750 V) with a frequency of up to 400 Hz or a constant voltage of up to 1000 V.

- They are used for laying in steel pipes, hollow channels of building structures, on trays, for installing electrical circuits, for installing indoor lighting networks, for laying power lines that are not subject to movement. In case of external wiring it is necessary to protect cables from mechanical damage and ultraviolet radiation. Therefore, it is necessary to use trays, conduits and wiring ducts.

operation: not below - 50°С

A – aluminum conductor;

P – wire;

V – PVC compound insulation;

«ngd» – does not support combustion, with reduced smoke and gas emission.

| Conductors: aluminum single-wire or multi-wire (class 1, 2 DSTU EN 60228) |

| Insulation: PVC compound |

| Armor: no |

| Number of conductors | Nominal cross-section area of the conductors, mm2 |

|---|---|

| 1 | 2,5 - 240 |

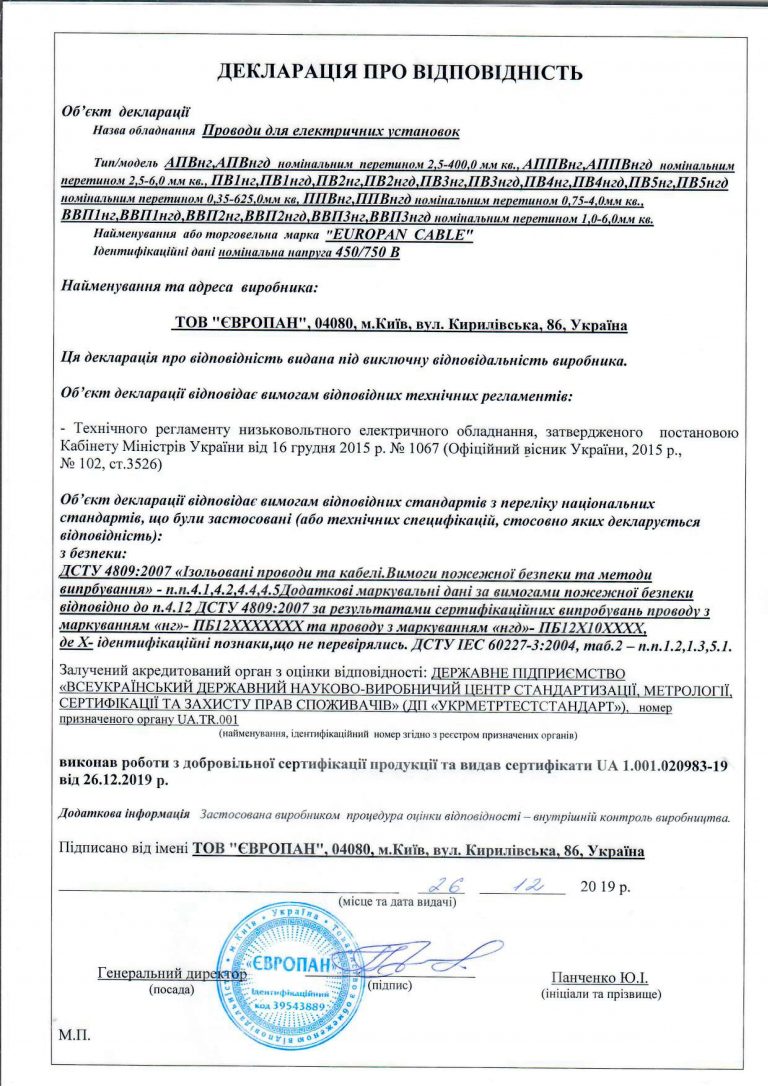

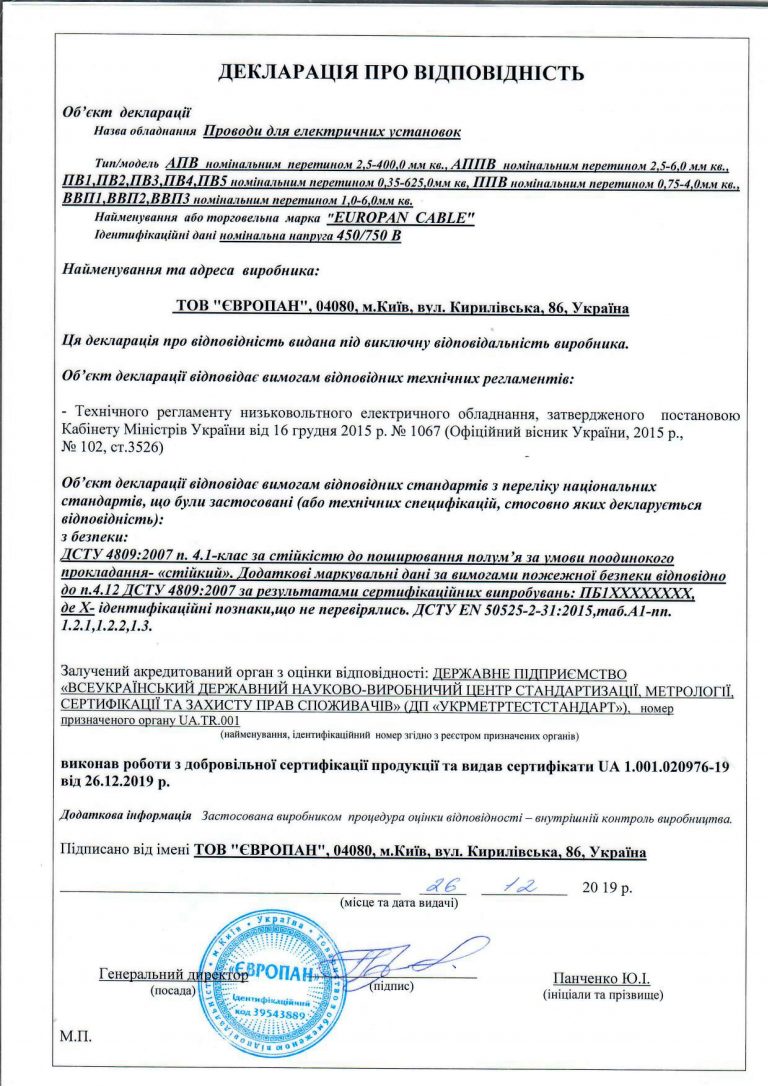

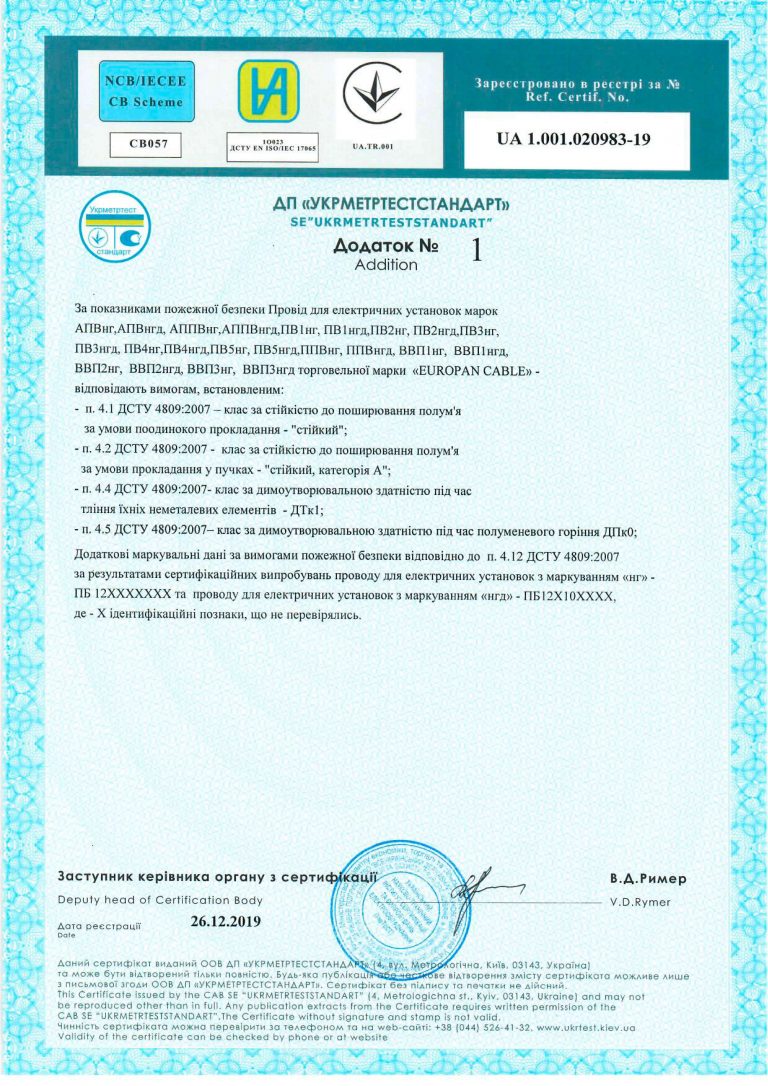

- The National Standards of Ukraine 4809:2007

- APV - PB 1XXXXXXXX

- APVngd - PB 122111XXX

APV wire refers to wires with aluminum conductor and PVC insulation. It is one of the most popular and has long been used in the industry.

Applicability scope

APV is used for electrical installations with stationary laying in lighting and power networks. And also for the installation of electrical equipment, machines, mechanisms and machine tools for a rated voltage of up to 450 V (for networks up to 450/750 V) with a frequency of up to 400 Hz or a constant voltage of up to 1000 V. It is used for laying in steel pipes, hollow channels of building structures, on trays, for the installation of electrical circuits and indoor lighting networks. It is also used for laying power lines that are not subject to movement. When performing external wiring, it is necessary to use protective equipment against mechanical damage and ultraviolet radiation, such as trays, conduits and wiring ducts.

APV wire with the «ngd» index is used in places with a high probability of fire and in conditions of increased requirements for fire safety. It is made using a special low fire hazard PVC with the low smoke generation. APVngd wire is resistant to flame propagation when laid in bundles.

Design

The wires design is based on aluminum single-wire or multi-wire conductors (class 1, 2 DSTU EN 60228), with a cross section of 2.5 – 240 mm2.

The APV manufacturing technology differs depending on its cross-section. As a rule, wires with a cross-section up to 16 mm2 are produced with one cast conductor of the corresponding cross-section. Up to this label size, the wire turns out to be quite flexible and convenient in installation. But with an increase in the cross-section, a wire consisting of one solid conductor becomes inconvenient in the installation. For this reason, APV wires with a nominal cross-section of 25 mm2 and more are produced consisting of several wires of a smaller cross-section, stranded together. This technology provides APV and APVngd with sufficient flexibility, reducing the risk of wire breakage due to repeated bends.

APV insulation is made of vinyl or as it is also called PVC plastic. And the bigger cross-section of the wire, the thicker its insulation is.

APV can be produced with the solid coloring or with coloring in the form of two stripes.

Operation

APV wires are intended for operation at an ambient temperature not lower than -50°С and a relative air humidity up to 100% at a temperature not higher than +35°С.

The laying without preheating of the wire is allowed at a temperature not lower than -15°С.

The minimum bend radius during installation must be at least 10 outer wire diameters.

The long-term permissible heating temperature of the wire conductors during operation is +70°C.

The service life is 15 years. The guaranteed service life is 2 years.

EUROPAN LLC website presents high-quality APV and APVngd wires from a reliable domestic manufacturer. All products are certified according to the legislation of Ukraine. You can familiarize yourself with the assortment, select and buy wires, cords, and other wiring products at wholesale prices on the company’s website or by contacting the sales department. Please contact the phone numbers listed on the website to get an advice, and for other questions.

Select rated voltage, kV

|

Nominal cross-section of conductor, mm2 |

Maximum outer diameter, mm |

Estimated weight of 1 km of wire, kg |

| 2,5 | 3,9 | 15 |

| 4,0 | 4,4 | 21 |

| 6,0 | 4,9 | 28 |

| 10 | 6,4 | 46 |

| 16 | 8,0 | 73 |

| 25 | 9,8 | 112 |

| 35 | 11,0 | 146 |

| 50 | 13,0 | 207 |

| 70 | 15,0 | 264 |

| 95 | 17,0 | 361 |

| 120 | 19,0 | 436 |

| 150 | 20,0 | 543 |

| 185 | 22,3 | 680 |

| 240 | 25,3 | 876 |

Select rated voltage, kV

|

Nominal cross-section of conductor, mm2 |

Maximum outer diameter, mm |

Estimated weight of 1 km of wire, kg |

| 2,5 | 3,9 | 17 |

| 4,0 | 4,4 | 22 |

| 6,0 | 4,9 | 30 |

| 10 | 6,4 | 49 |

| 16 | 8,0 | 77 |

| 25 | 9,8 | 119 |

| 35 | 11,0 | 153 |

| 50 | 13,0 | 217 |

| 70 | 15,0 | 276 |

| 95 | 17,0 | 376 |

| 120 | 19,0 | 452 |

| 150 | 20,0 | 564 |

| 185 | 22,3 | 706 |

| 240 | 25,3 | 908 |