PV1, PV1ngd

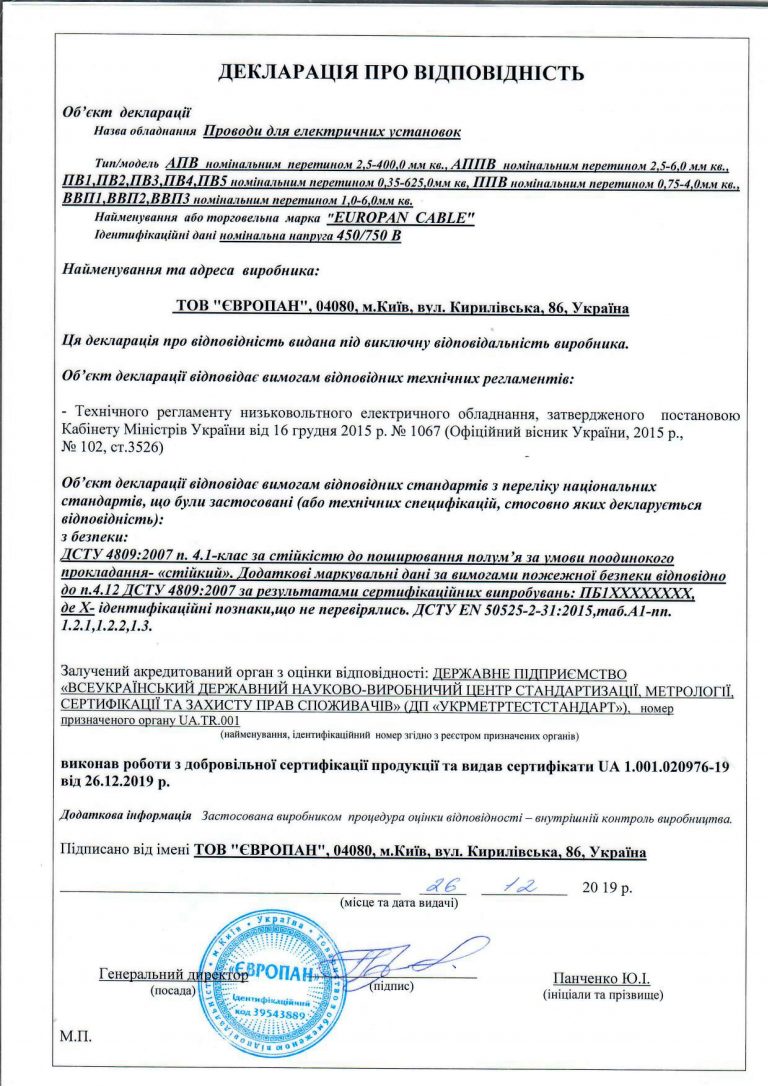

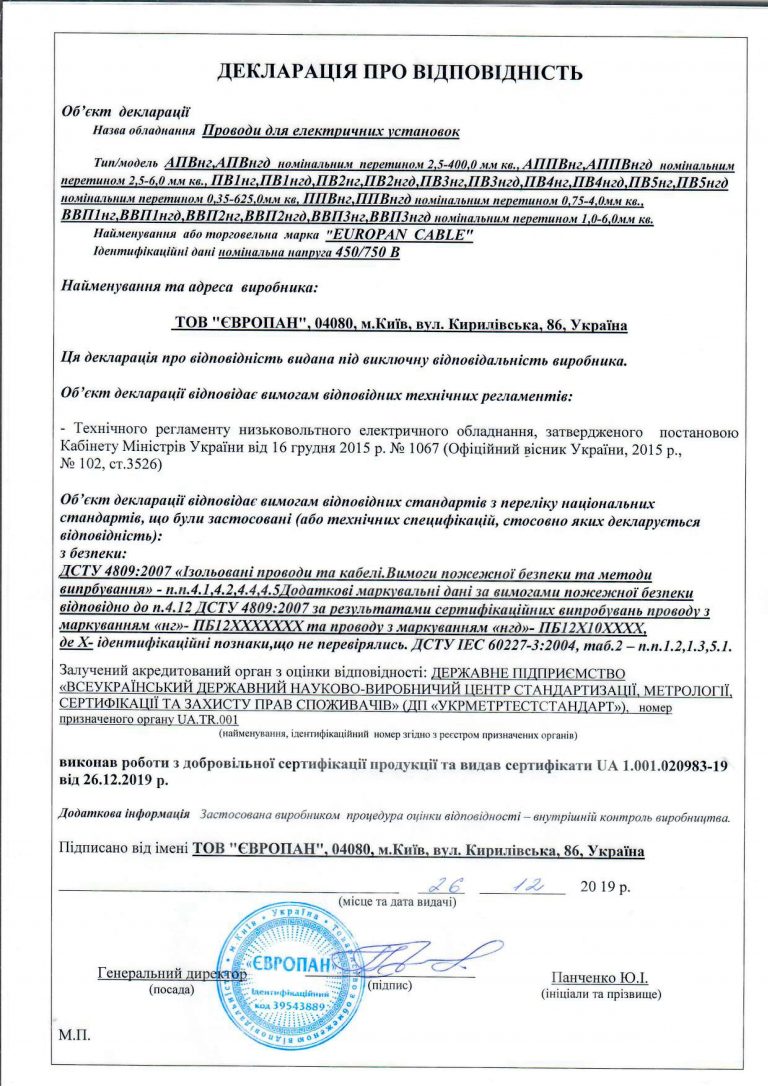

- PV1, PV1ngd are wires with the copper conductor and PVC insulation.

- They are designed for electrical installations with stationary laying in lighting and power networks, as well as for the installation of electrical equipment, machines, mechanisms and machine tools for a rated voltage of up to 450 V (for networks up to 450/750 V) with a frequency of up to 400 Hz or a constant voltage of up to 1000 V.

- They are used for laying in steel pipes, hollow channels of building structures, on trays, for installing electrical circuits, installing indoor lighting networks and for laying power lines that are not subject to movement.

- If it is necessary to carry out external wiring, it is required to use trays, conduits, wiring ducts that protect the wire from mechanical damage and ultraviolet radiation.

operation: down to -50°С

The copper conductor is not indicated on the marking;

P – wire;

V – PVC compound insulation;

1 – flexibility class of the conductor;

«ngd» – does not support combustion, with reduced smoke and gas emission.

| Conductors: copper, single-wire or multi-wire (class 1, 2 of the National Standards of Ukraine EN 60228) |

| Insulation: PVC compound |

| Armor: no |

| Number of conductors | Nominal cross-section area of the conductors, mm2 |

|---|---|

| 1 | 0,5 - 240 |

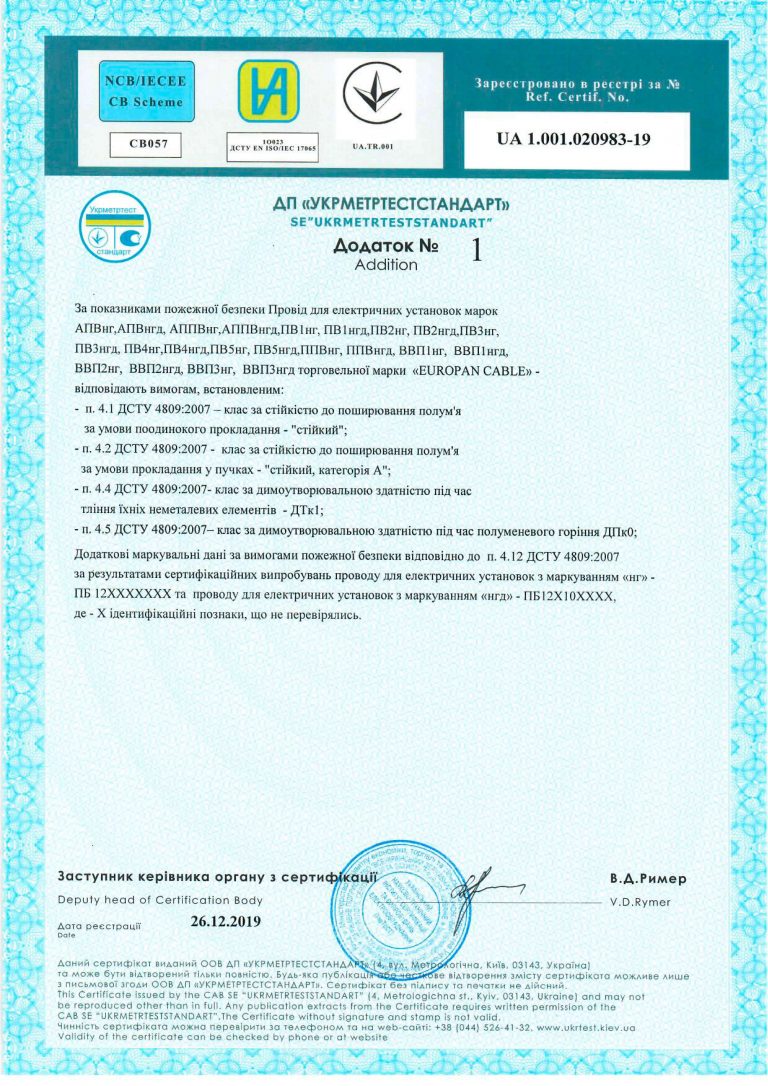

- The National Standard of Ukraine 4809:2007

- PV1 - PB 1XXXXXXXX

- PV1ngd - PB 122111XXX

PV1 is a single-conductor copper wire with PVC insulation. It is designed for the stationary electrical installations in the lighting and power networks. It is also intended for the installation of electrical equipment, machines, mechanisms and machine tools for a rated voltage of up to 450 V (for networks up to 450/750 V) with a frequency of up to 400 Hz or a constant voltage of up to 1000 V.

Application scope

PV1 is widely used both in production and in everyday life. In particular, for laying lines from the grounding element to the device or outlet, for conducting lightning discharges into the ground, installing electrical wiring, connecting electric motors and low-voltage equipment. It is used for laying in steel pipes, hollow channels of building structures, metal hoses, on trays, for installing electrical circuits and indoor lighting networks.

Unlike PV3, which can withstand multiple movements, PV1 is designed for long-term operation in stable position. And it is used to lay power lines that are not subject to movement. If it is necessary to carry out external wiring, it is required to use trays, conduits, wiring ducts that protect the wire from mechanical damage and ultraviolet radiation.

Design

The conductive element of the PV1 wire is copper single-wire or multi-wire conductors. They are made of tinned copper of the 1st and 2d flexibility classes (class 1, 2 of the National Standards of Ukraine EN 60228), with a cross-section from 0.5 to 240 mm2. The structure and technical characteristics of the conductor change depending on its cross-section. So, wires with a cross-section from 0.5 to 10 mm2 are made with a solid core and belong to the 1st class of flexibility. Starting from a cross-section of 16 mm2, wires are made using the multi-wire conductors. Besides the number of wires from which the conductor is stranded increases as the wire cross-section increases. Although such wires are called PV1, they belong to the 2nd flexibility class.

The insulation of PV1 is made of polyvinyl chloride material and can have different colors. And its thickness depends on the wire cross-section.

Wire with the index «ngd» is made using a special PVC with a low fire hazard and low smoke-generation. PV1ngd is used in places with a high probability of fire, in conditions of increased requirements for fire safety, for laying in bundles, as well as laying in plastic and steel channels.

Operation

PV1 and PV1ngd are designed for operation at ambient temperatures down to -50°C. They are sufficiently moisture resistant and, at temperatures not exceeding +35°C, are capable of operating at a relative humidity of 100%.

Laying without preheating of the wire is allowed at a temperature not lower than -15°С.

The minimum bend radius during installation must be at least 10 outer wire diameters.

Long-term permissible heating temperature of cable conductors during operation is +70°С.

The service life of the wires is 15 years. The guaranteed service life is 2 years.

The website of EUROPAN LLC presents wires PV1 and PV1ngd of various cross-sections, high quality, certified in accordance with the legislation of Ukraine. They are distinguished by high electrical performance and an affordable price. As a direct manufacturer, we can offer our clients low prices, and our experts will help you choose the right product with suitable characteristics and ensure optimal delivery times. To order products and consultation, you can contact the specialists of EUROPAN LLC at the numbers indicated on the website.

Select rated voltage, kV

|

Nominal cross-section of the conductor, mm2 |

Maximum outer diameter, mm |

Estimated weight of 1 km of wire, kg |

| 0,5 | 2,4 | 8 |

| 0,75 | 2,6 | 11 |

| 1,0 | 2,8 | 13 |

| 1,5 | 3,3 | 19 |

| 2,5 | 3,9 | 31 |

| 4,0 | 4,4 | 45 |

| 6,0 | 4,9 | 65 |

| 10 | 6,4 | 107 |

| 16 | 8,0 | 173 |

| 25 | 9,8 | 270 |

| 35 | 11,0 | 364 |

| 50 | 13,0 | 519 |

| 70 | 15,0 | 696 |

| 95 | 17,0 | 954 |

| 120 | 19,0 | 1177 |

| 150 | 20,0 | 1463 |

| 185 | 22,3 | 1836 |

| 240 | 25,3 | 2380 |

Select rated voltage, kV

|

Nominal cross-section of the conductor, mm2 |

Maximum outer diameter, mm |

Estimated weight of 1 km of wire, kg |

| 0,5 | 2,4 | 9 |

| 0,75 | 2,6 | 11 |

| 1,0 | 2,8 | 14 |

| 1,5 | 3,3 | 20 |

| 2,5 | 3,9 | 32 |

| 4,0 | 4,4 | 47 |

| 6,0 | 4,9 | 67 |

| 10 | 6,4 | 110 |

| 16 | 8,0 | 178 |

| 25 | 9,8 | 276 |

| 35 | 11,0 | 372 |

| 50 | 13,0 | 529 |

| 70 | 15,0 | 707 |

| 95 | 17,0 | 970 |

| 120 | 19,0 | 1194 |

| 150 | 20,0 | 1484 |

| 185 | 22,3 | 1862 |

| 240 | 25,3 | 2412 |