Power cables with copper and aluminum conductors

Power cables are conductors designed to transmit and distribute electrical energy. They are used to transferring heavy currents of industrial frequency from electrical substations, energy companies, and public utilities to switchgear and ultimate users. They serve to power electrical appliances and electrify buildings, structures, residential buildings and even entire cities, regions and countries. They allow to connect fixed installations and mobile units. They can be laid underground, in water, at a height, or simply laid on the surface.

There are many different classifications of power cables. For example, according to the voltage level, the models are distinguished for those conducting up to 1000 V and cables for high-voltage networks, conducting over 1000 V.

Depending on the laying method, there are cables for fixed installations and mobile units. Additionally, cables are distinguished according to their design features – depending on the number, structure and flexibility of conductors, alloy of conductors, type of insulation, cross-sectional area, voltage and other characteristics.

The design and the form of execution of power cables depend on the laying conditions and the scope of use. Its required elements are insulated copper or aluminum conductors in an inner sheath. In addition, the cable may have core wrapping insulation, infill, shield, armour, and bedding under the armour. Cable marking helps to indicate all these features consisting of the initial letters of the words describing the design of the cable and numbers indicating the number of conductors, cross-sectional area and voltage.

The conductor of a power cable can consist of one wire – a solid conductor, or several thin interwoven wires – a multi-wire conductor. It is this parameter that determines the flexibility of the conductor – the more wires it has, the better it bends. The number of conductors of power cables varies from 1 to 5. They can be round or sector-shaped, laid parallel or stranded.

The main task of the insulating layer is to protect a human from contact with a current-carrying conductor. Moreover, insulation allows several conductors to be placed nearby without a short circuit risk.

The type of insulation material depends on the scope of the cable use, and the most common material is PVC compound and cross-linked polyethylene. They protect the conductors from short circuits, mechanical damage, moisture, light, chemicals and other external influences.

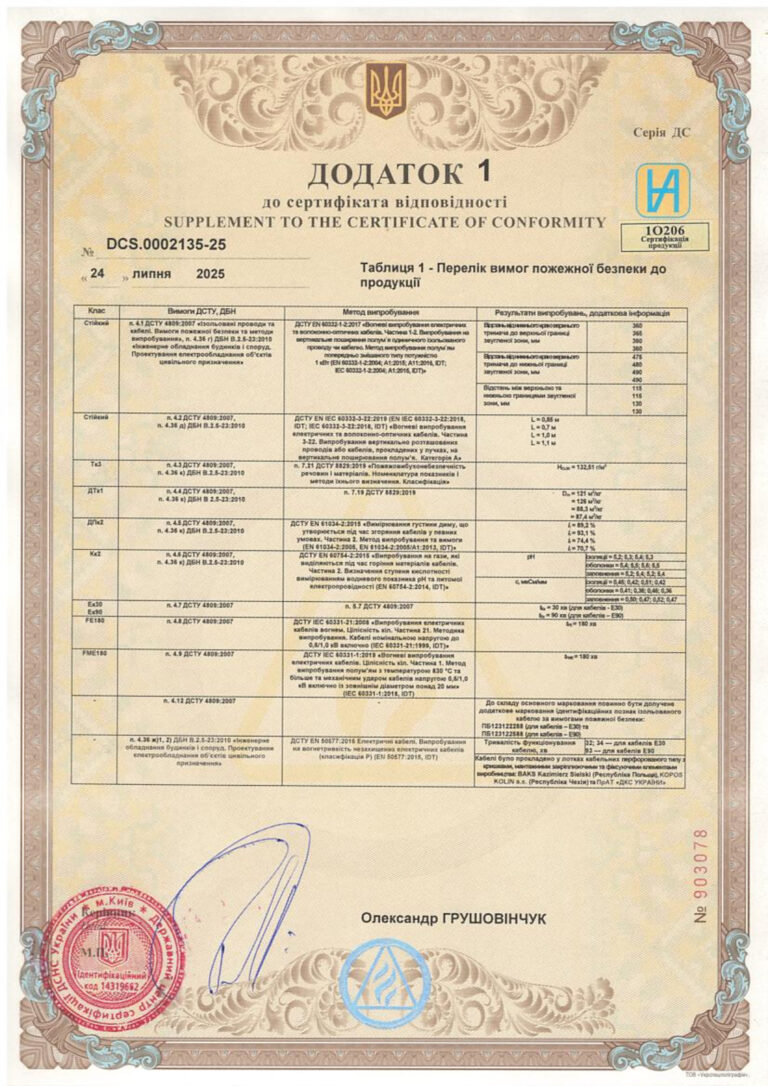

There are also low fire-hazard cables, which do not spread flame when laid alone and in bundles, as well as fire-resistant cables with low levels of smoke, gas, and other toxic substances, which are used mainly in public places with large crowds.

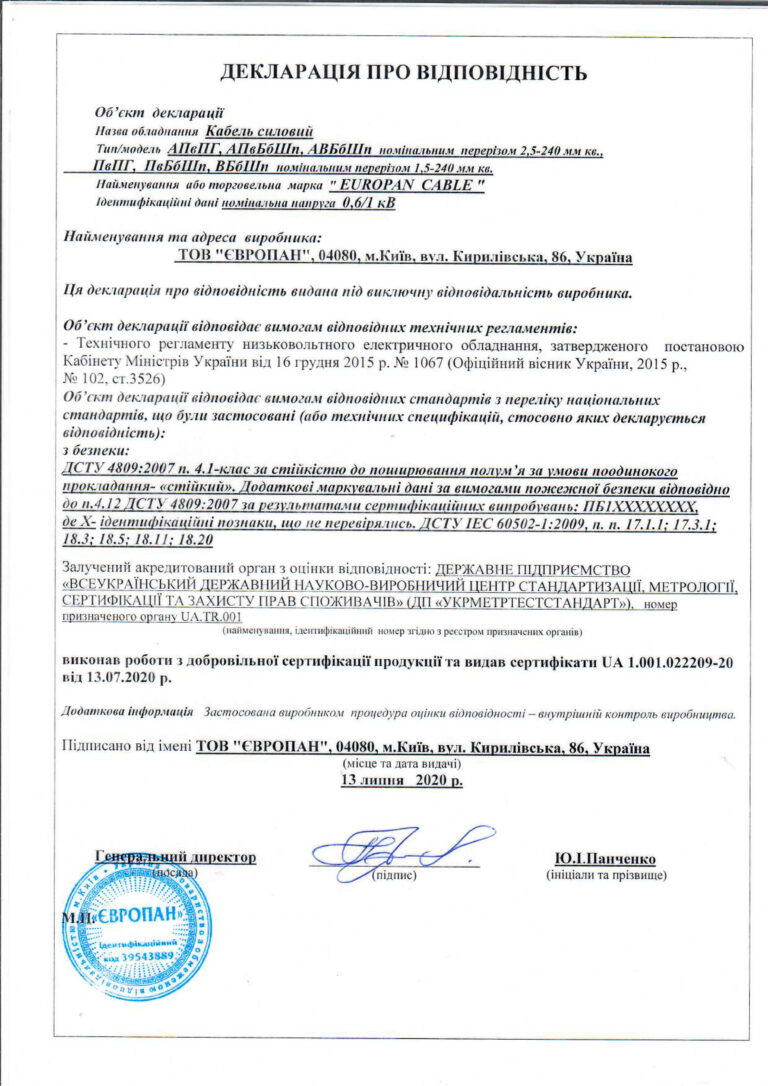

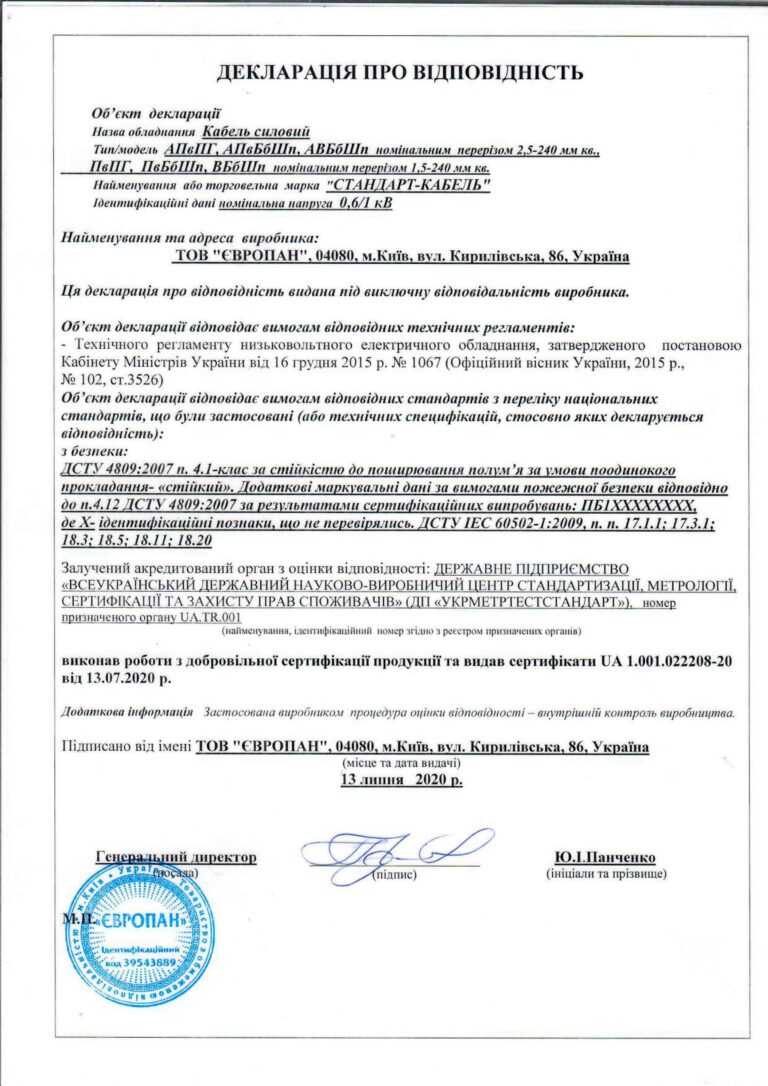

Europan Cable Plant produces reliable and long-life power cables, single and multi-core, shielded, armoured, flexible and for fixed installation, flat and fire-resistant, designed for transmission and redistribution of the current in industry, agriculture and household sector, wherever there is the need for electrical power. A wide product range allows each consumer to find the best option, depending on the destination, the loading and the type of network.