Control cables with copper and aluminum conductors

Control cables are a separate group of cable and wire products. They are considered to be intermediate between communication cables and power cables. Most often they are used for secondary switching of remote control devices for activation of systems and regulating starting. They are used to build command and control lines, protective relay, signaling, blocking networks, remote control, as well as to connect electrical instruments and apparatus to other control devices.

They conduct and transmit currents of small strength and voltage up to 1 kV. There are control cables for fixed installation and movable connection. The former ones are used for fixed installation outdoors or on the ground, and the latter ones are used for mobile mechanisms. The control cable is mainly used for connection to stationary electrical apparatus and devices.

The design feature of this group of cables is a large number of conductors, which can reach 61. The conductors may be copper or aluminum. If the cable is designed to connect stationary devices and is not exposed to bends and dynamic loads, the conductors are made in the form of a single wire. If the purpose is to connect mobile, portable electrical installations, the conductors are made flexible, in the form of stranded wires, providing the flexibility of the conductors. Conductor diameter with a large cross-section is suitable for precision measuring systems sensitive to voltage drops.

Cables with copper conductors have higher conduction, corrosion resistance, they are more elastic and offer better resistance to bending. At the same time, the main disadvantage of a copper cable is its high price.

Aluminum cable is much less flexible and prone to air oxidation. Due to this fact, a film could appear on the surface of its elements. The latter shows weak conduction and prevents the formation of intimate contact. This in turn leads to excessive overheating and sparks, one of the main causes of fires. At the same time, cables with aluminum conductors are lightweight, which facilitates their installation and transportation. They are of low cost, which makes them very popular among consumers.

The conductors of the cable are insulated, combined into one bundle and stranded into a certain number of turns, allowing easy bending of the cable, and placed in common insulation. Insulation can be made of rubber, polyethylene, or PVC compound with mandatory color or numerical marking, which makes it easier to identify the conductors during installation. Control cables may also be armoured, made with filling in the inter-conductor space and a protective shield. And a corrugated conduit or a metal bandage is used for protection from external influences. All these features are shown on the cable label.

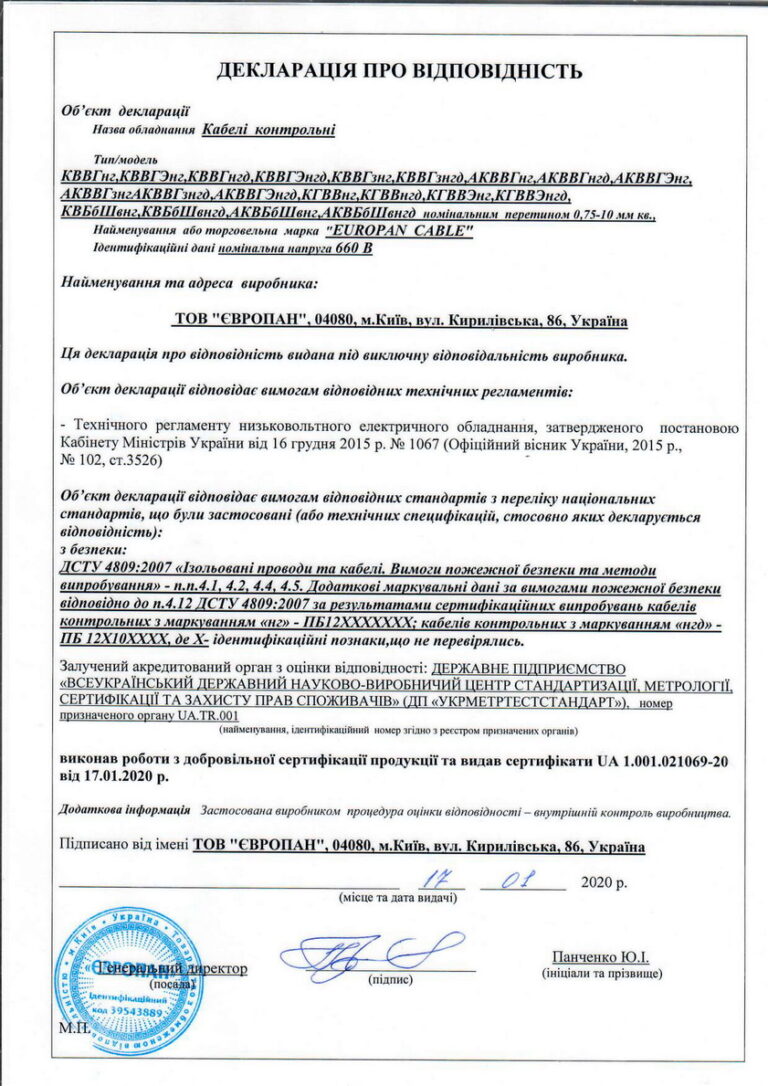

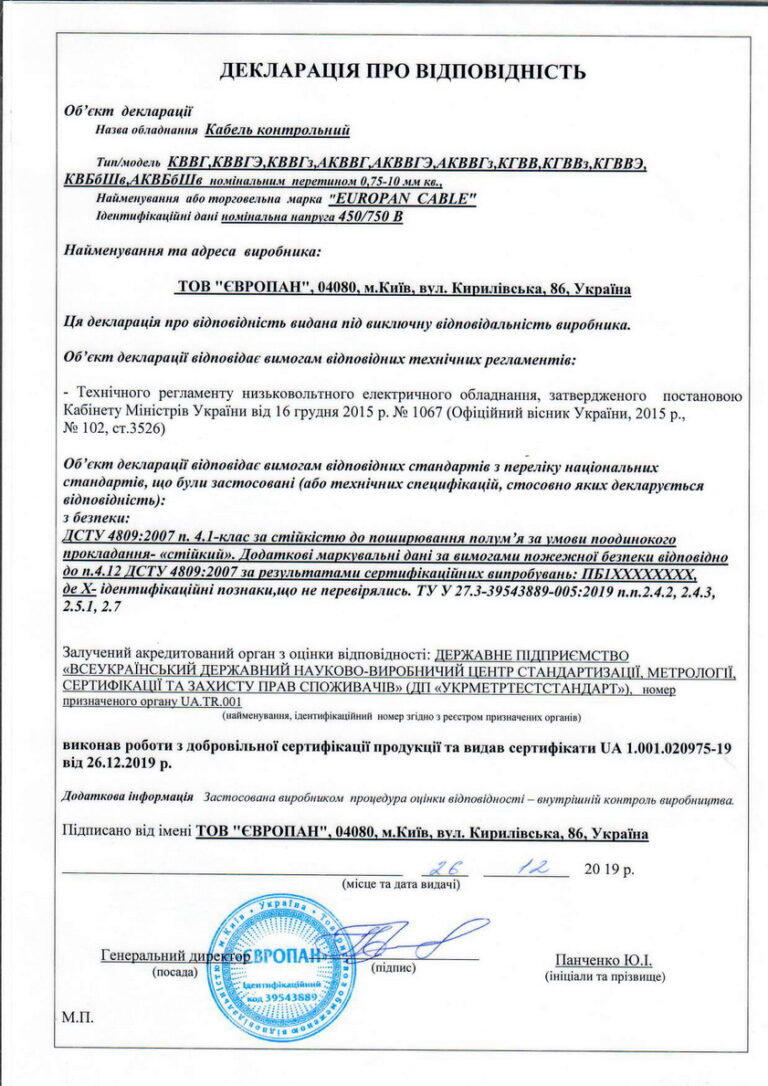

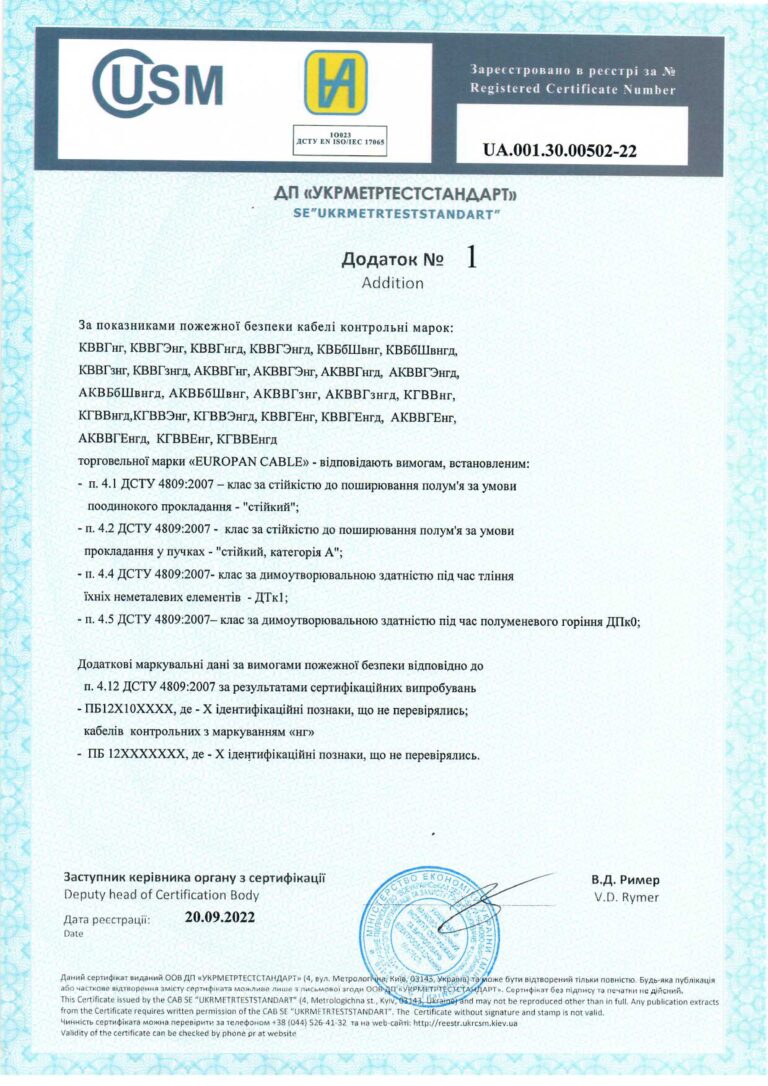

Europan Cable Plant produces control cables of various types and sizes, flexible and designed for fixed installation, shielded and armoured, filled and made of fire-resisting insulating materials. All of them can be used in control panels of electric power plants, industrial installations, for secondary switching of starting and regulating remote control equipment, protective relay and automation, as well as for connecting electrical appliances and apparatus. Even the most demanding consumers would be satisfied with the wide assortment combined with high quality of products.