Wires and cords with copper and aluminum conductors

A wire, also called an electric wire, is a current conductor, consisting of one or more stranded wires, which serves to connect a source of electric current to a consumer or components of an electrical circuit. Most often, wires are used when laying overhead power lines, installing lighting networks, producing winding for electrical machines, installing radio equipment, electric equipment, machines, mechanisms, machine tools, as well as in communications. The wire is not intended to be laid in the ground or underwater.

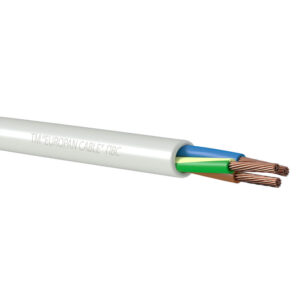

A cord is a type of wire with highly flexible insulated copper conductors designed for portable equipment and for connecting household appliances and equipment to the power grids. It consists of multi-wire conductors with a cross-section of up to 1.5 mm2 with rubber or PVC insulation.

Wires’ conductors are made mainly of copper or aluminum wire, they can be solid or stranded with a large number of wires to increase the flexibility of the conductor. There are also combined wires with a steel core, with one or more turns of aluminum wire wound thereon. A light non-metallic sheath made of cross-linked polyethylene or PVC compound, as well as winding or braiding of fibrous materials, may be applied above the conductors, depending on the conditions of laying and operation. Wire marking consists of letters and numbers. The first letter indicates the material of the conductor, the remaining letters indicate the type of product, the material of insulation and protection, and the numbers indicate the number of conductors and the cross-section.

The marking of cords is similar to the marking of wires, save for the letter “SH” at the beginning.

Wires, like cables, are distinguished by the number of conductors, cross-section, and rated voltage that could be conducted. According to the number of wires, there are solid and multi-wire conductors, according to the conductor material – aluminum, copper, steel-aluminum and steel, according to flexibility – flexible and rigid, according to the degree of protection – insulated and bare, and insulated wires, in their turn, are protected and unprotected.

Unprotected wires have only insulation. And protected wires are those whose insulated wires have an outer sheath in the form of a metal braid that protects the wire from external influences and mechanical damage.

Bare wires are the simplest, they are quite dangerous because if you come into contact with them, you can get an electric shock. They are predominantly made of aluminum and are used mainly for laying overhead power lines, electric transport contact networks and antenna devices. They are suspended on supports or steel-wire ropes using electrical insulators and special fittings.

Another type of wire classification divides them into winding, building and hook-up.

Winding wires are used for the manufacture of windings of electrical machines, apparatus, transformers and instruments. Most often they are used in the manufacture of electric motors and arc welding machines. The conductors are mainly copper, less often aluminum, the cross-section is round or rectangular, the insulation is light: enamel, paper, fiberglass or cotton. There are also high-voltage winding wires designed for voltages above 1000 V, with heat-resistant insulation and high-frequency ones, designed for frequencies from tens of kilohertz to hundreds of megahertz.

Hook-up wires are most often used to transfer current inside electrical appliances, perform group connections in various circuits, electrical and radio engineering devices, connect devices and apparatus on regulating stations and control panels. The conductors of such wires are usually copper, of round cross-section, including those coated with silver, nickel and timing, with polyethylene or polyvinyl chloride insulation.

Building wires are intended for stationary installation of power and lighting power grids outdoors and indoors, including for non-exposed installation under the plaster, connecting to electric motors networks, lamps and power supply to various portable equipment and devices. They come in copper and aluminum, mostly of the round cross-section with rough and high-quality, most often PVC or rubber insulation. Also, polyethylene, asbestos, fiberglass or rubber-fiberglass can be used as an insulating material. Sometimes these wires can be placed in a thin metal protective tube.

As you can see, structurally, the wire is quite simple in execution, it can consist of only one “bare” conductor, or have insulation, sheath and coating. Nevertheless, the wires and cords are not equipped with serious protection, and their voltage stress usually does not exceed 660 V. At the same time, the wire is a must-have for distributing electric current in an apartment or a house, a stranded wire is used for a movable connection, and a cord is used for connecting to networks of household electrical appliances and radio equipment. Wires and cords are relatively cheap in comparison with cables, and when choosing them, it is necessary to take into account the laying conditions and operating voltage.