A

- A is a bare wire, stranded from the aluminum wires.

- It is designed for the transmission of the electrical energy in overhead networks.

- It is used for the distribution of the electrical energy in overhead electrical networks. Wire laying is carried out by air on power transmission line supports in accordance with the rules for the installation of electrical installations and the rules for the technical operation of the power plants and networks. During its use, the concentration of the sulfur dioxide should not exceed 150 mg/m2.

The long-term permissible temperature of the wires during operation should not exceed 90°С

A – aluminum (the conductor is multi-wire, stranded form the aluminum wires)

| Conductors: aluminum multi-wire |

| Insulation: no |

| Armor: no |

Brand A wire refers to the group of uninsulated or, as they are also called, «bare» wires. In modern electrical networks, most overhead lines are made with just such wires.

Applicability scope

Uninsulated aluminum wire of brand A, is primarily intended for the transmission and distribution of electricity in overhead electrical networks. It can also be used for electric transport lines, the establishment of high-voltage power lines in residential, industrial and other structures, as well as in distribution circuits of electrical machines and devices, switchgear and substations.

Wire laying is carried out by air on power transmission line supports in accordance with the rules for the installation of electrical installations and the rules for the technical operation of the power plants and networks. It is not recommended to lay this wire in places with a high risk of mechanical damage.

Design

Bare wires work in very difficult conditions, because they are in the open air and are constantly under the influence of various atmospheric phenomena. They must withstand temperature extremes, adhesion of snow and ice, gusts of wind, as well as chemical impurities in the surrounding air. That is why, in addition to the good electrical conductivity, such wires must have sufficient mechanical strength and corrosion resistance. The design of a wire of brand A is based on a stranded conductor made of aluminum wires. After all, it is stranded wires that have greater mechanical strength and flexibility compared to single-wire ones. The wires are stranded into one conductor with a special twist. The twisting of adjacent layers is made in opposite directions, and the outer twisting is made to the right. This type of twisting gives the wire a rounder shape and helps to avoid unwinding as much as possible. There is no insulation in the A-brand wires, that is why this wire is also called «bare».

Operation

Wire A is used in air of types I and II, provided that the content of sulfur dioxide in the atmosphere is not more than 150 mg/m2. It is used exclusively on land in all macroclimatic regions. It is suitable for areas with sudden temperature changes and is efficient within the range from -60°C to +40°C.

Permissible continuous current loads on the bare wires depend on the installation location and operating conditions. In this case, the long-term permissible heating of the conductors of wire should not exceed +90°C.

The bend radius during installation and the wire installed on the supports is at least 10 maximum outer diameters of the wire.

The minimum service life is 45 years. The guaranteed service period is 4 years.

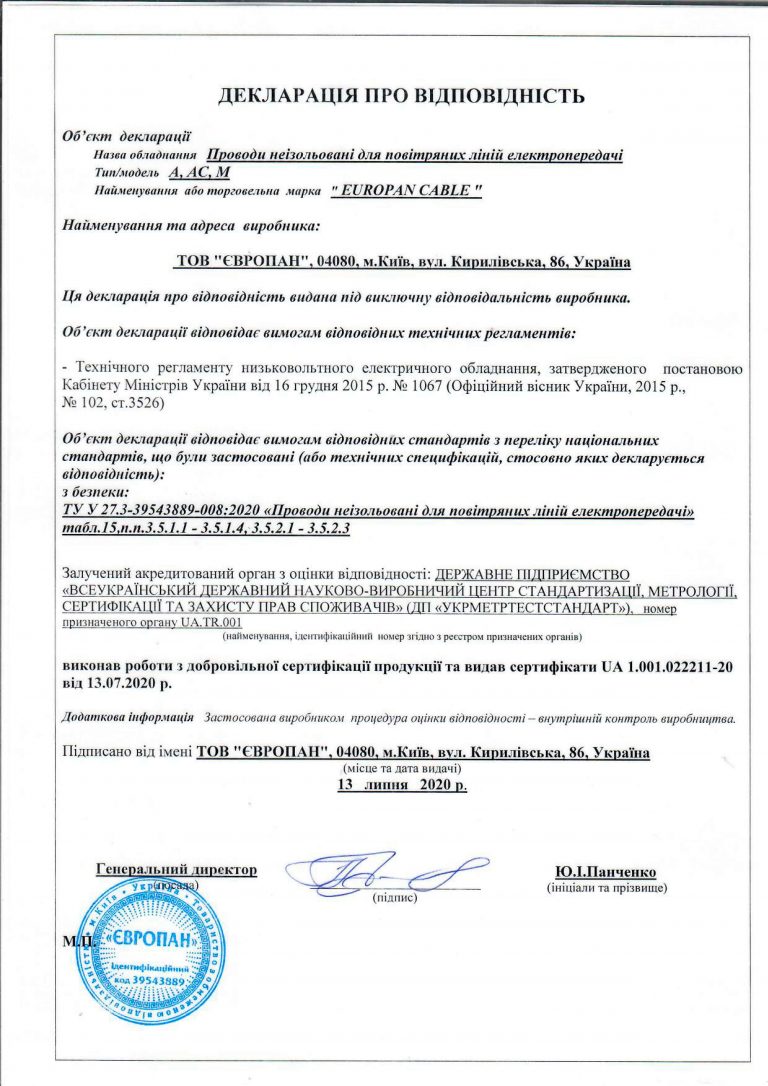

Brand A wires are extremely demanded, they guarantee a high reliability, have good electrical conductivity, light weight, are easy to install and affordable. The website of EUROPAN LLC presents an aluminum uninsulated wire of brand A with a total cross-section from 16 to 500 mm2, as well as other cable and wire products. All goods are certified and available for ordering with delivery directly to the installation site in any city in Ukraine. Our experts will help you choose a conductor, offer you favorable prices and terms of purchase.

Select rated voltage, kV

|

Nominal cross-section, mm2 |

Outer diameter, mm |

Weight of 1 km of wire, kg |

Electrical resistance of 1 km of wire to direct current at 20 °С, Ohm, no more than |

Breaking strength of the wire, N, not less than |

| 16 | 5,10 | 43,0 | 1,8007 | 3021 |

| 25 | 6,39 | 68,0 | 1,1498 | 4500 |

| 35 | 7,50 | 94,0 | 0,8347 | 5913 |

| 40 | 8,10 | 109,4 | 0,7157 | 6800 |

| 50 | 9,00 | 135,0 | 0,5784 | 8198 |

| 63 | 10,17 | 172,3 | 0,4544 | 10390 |

| 70 | 10,65 | 189,0 | 0,4131 | 11288 |

| 95 | 12,30 | 252,0 | 0,3114 | 14784 |

| 100 | 12,95 | 274,9 | 0,2877 | 17000 |

| 120 | 14,00 | 321,0 | 0,2459 | 19890 |

| 125 | 14,45 | 343,6 | 0,2301 | 21250 |

| 150 | 15,75 | 406,0 | 0,1944 | 24420 |

| 160 | 16,35 | 439,8 | 0,1798 | 26400 |

| 185 | 17,50 | 502,0 | 0,1574 | 29832 |

| 200 | 18,30 | 549,7 | 0,1438 | 32000 |

| 240 | 20,00 | 655,0 | 0,1205 | 38192 |

| 250 | 20,45 | 687,1 | 0,1150 | 40000 |

| 300 | 22,05 | 794,0 | 0,1000 | 47569 |

| 315 | 23,03 | 867,5 | 0,0915 | 51970 |

| 350 | 24,15 | 952,0 | 0,0833 | 57057 |

| 400 | 25,62 | 1072,0 | 0,0740 | 63420 |

| 450 | 27,30 | 1206,0 | 0,0642 | 71856 |

| 500 | 29,05 | 1378,0 | 0,0576 | 80000 |