VBbSHp

- VBbShp is a power cable with copper conductors, PVC insulation and a BbSHp- type protective sheath.

- It is designed for the transmission and distribution of electrical energy in stationary installations for a rated alternating voltage of 0.66; 1 kV with a frequency of 50 Hz.

- It is used for laying in the ground (in trenches), rooms, tunnels, channels, mines (except for laying in blocks), partially flooded structures with various corrosive conditions, as well as outdoors, if the cable is not subjected to significant tension strain, but if there is a risk of mechanical damage during operation.

Multi-conductor cable: 7.5 x outer diameter

operation: from -50°С to +50°С

The copper conductor is not indicated in the cable marking;

V – PVC-compound insulation;

B – armor made of galvanized steel bands;

b – without a bedding under the armor;

SHp – extruded protective hose made of light-stabilized polyethylene.

| Conductors: copper single-wire or multi-wire of the 1st or 2d flexibility class, round or sector shape (class 1, 2 DSTU EN 60228) |

| Insulation: the conductors insulation is made of PVC compound, the hose-type sheath made of light-stabilized polyethylene |

| Armor: galvanized steel bands |

| Rated voltage, kV | ||

|---|---|---|

| 0,66 | 1 | |

| Number of conductors | Nominal cross-section area of the key conductors, mm2 | |

| 1 | 10 — 50 | 10 — 240 |

| 2, 3, 4, 5 | 2,5 — 50 | 2,5 — 240 |

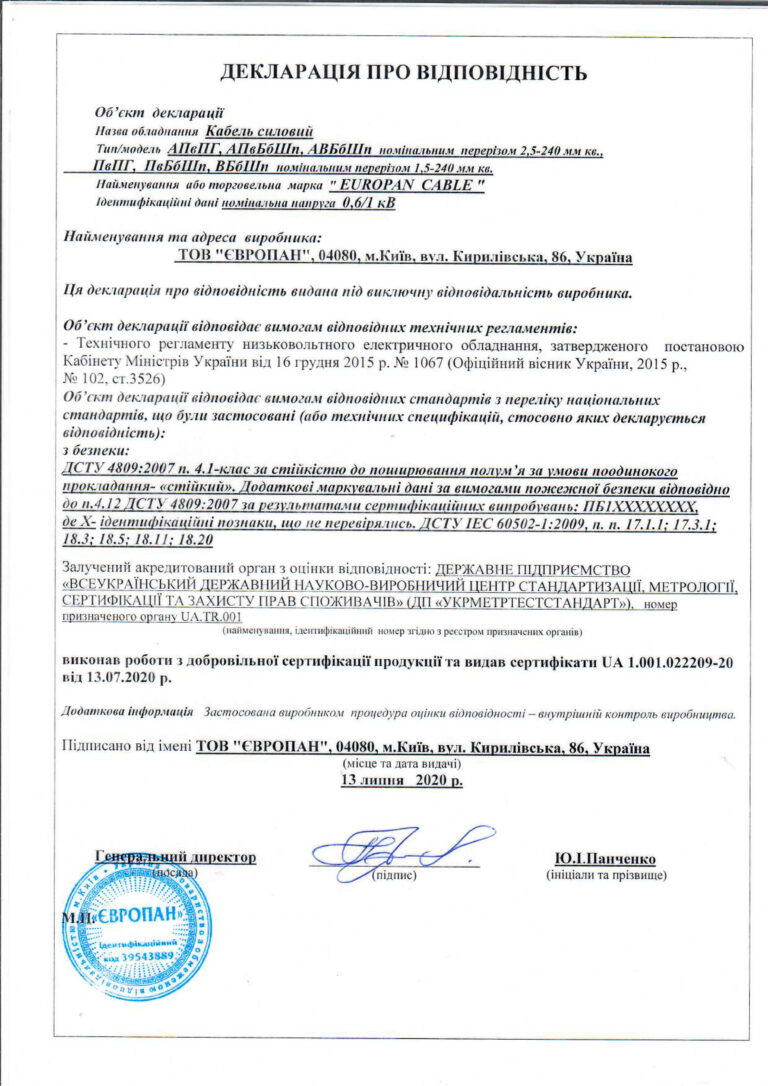

- The National Standards of Ukraine 4809:2007

- VBbSHp - PB 1XXXXXXXX

VBbSHp is a power cable with copper conductors, PVC insulation and a BbSHp-type protective sheath. It is designed for the transmission and distribution of electrical energy in stationary installations for a rated alternating voltage of 0.66; 1 kV with a frequency of 50 Hz.

Applicability scope

Armoured cable VBbSHp has a very wide scope of applicability and is quite universal. It can be used for all weather conditions and soils, including leakage currents presence and places where the soil is chemically active with respect to metal. It withstands temperature changes and resists various mechanical influences. The armor made of steel bands protects VBbSHp from the damage by rodents and impacts by the tools during excavation work in places where cable lines pass.

Since the cable has little flexibility and low tensile strength, it is mainly used for the laying in earthen trenches and outdoors when there is a risk of mechanical damage during operation and provided there is a low tension strain. However, it can also be used for laying in rooms, tunnels, channels, mines (except for laying in blocks) and partially flooded structures with various corrosive conditions. It withstands high electrical and mechanical loads, is not susceptible to damage in high humidity conditions and is suitable for laying in various corrosive conditions. It is also easy to install, since it does not require additional devices for laying in the form of pipes and concrete conduits.

It is widely used to connect electrical equipment in the industrial and residential areas. It can be used for installation in rooms with a high level of fire hazard. Moreover, it is flame-retardant in case of single laying while the fireproofing is required in case of group laying.

Design

VBbSHp design is based on copper, single-wire or multi-wire conductors, round or sector shape (class 1, 2 DSTU EN 60228). The conductors insulation and the inner sheath of the cable are made of PVC compound. The armor is made of galvanized steel bands, and the extruded protective hose made of light-stabilized polyethylene serves as a protective coating.

Operation

The cable is designed for stationary operation at the ambient temperatures from -50°C to +50°C, the relative air humidity up to 98% at temperatures up to +35°C. The laying is possible at a temperature not lower than -15°С, otherwise preheating of the cable is required.

The minimum bend radius during the installation must be at least 7.5 outer cable diameters for multi conductors cables and 10 outer cable diameters for single-conductor cables.

The long-term permissible conductors heating temperature during operation is 70°C. The maximum permissible temperature at short-circuit currents is 160°С, and in an emergency mode no more than 80°С.

The service life of the cables is 30 years. The guaranteed service life is 5 years.

EUROPAN Cable Plant produces copper armoured power cable VBbShH and its aluminum analogue AVBbSHp. The cables are certified in accordance with the Ukrainian legislation and meet international quality standards. As a direct manufacturer, we offer our customers high-quality cable and wire products at the most favorable prices. Our managers will provide advice and assistance in selecting of the products, as well as ensure the convenient shipping date

Permissible short circuit currents of cables

|

Nominal conductor cross-section, mm² |

Permissible current of one-second short circuit of cables, kA |

Nominal conductor cross-section, mm² |

Permissible current of one-second short circuit of cables, kA |

| 2,5 | 0,27 | 50 | 5,23 |

| 4,0 | 0,43 | 70 | 7,54 |

| 6,0 | 0,65 | 95 | 10,48 |

| 10 | 1,09 | 120 | 13,21 |

| 16 | 1,74 | 150 | 16,30 |

| 25 | 2,78 | 185 | 20,39 |

| 35 | 3,86 | 240 | 26,80 |

Select rated voltage, kV

|

Number of conductors and nominal cross-section, mm2 |

Nominal outer diameter, mm |

Estimated weight of 1 km of cables, kg |

| 1 x 10 | 12,0 | 272 |

| 1 x 16 | 13,5 | 368 |

| 1 x 25 | 15,2 | 498 |

| 1 x 35 | 16,4 | 615 |

| 1 x 50 | 18,5 | 807 |

| 2 x 2,5 | 12,6 | 237 |

| 2 x 4,0 | 13,9 | 295 |

| 2 x 6,0 | 15,2 | 363 |

| 2 x 10 | 17,5 | 496 |

| 2 x 16 | 20,8 | 690 |

| 2 x 25 | 24,4 | 960 |

| 2 x 35 | 26,9 | 1208 |

| 2 x 50 | 31,0 | 1613 |

| 3 x 2,5 | 13,1 | 275 |

| 3 x 4,0 | 14,7 | 357 |

| 3 x 6,0 | 15,8 | 440 |

| 3 x 10 | 18,3 | 610 |

| 3 x 16 | 21,9 | 883 |

| 3 x 25 | 25,9 | 1267 |

| 3 x 35 | 28,4 | 1604 |

| 3 x 50 | 32,8 | 2173 |

| 3 x 4,0 + 1 x 2,5 | 15,6 | 405 |

| 3 x 6,0 + 1 x 4,0 | 16,6 | 507 |

| 3 x 10 + 1 x 6,0 | 19,2 | 692 |

| 3 x 16 + 1 x 10 | 23,0 | 1012 |

| 3 x 25 + 1 x 16 | 28,1 | 1486 |

| 3 x 35 + 1 x 16 | 30,1 | 1821 |

| 3 x 50 + 1 x 25 | 35,3 | 2516 |

| 4 x 2,5 | 13,8 | 319 |

| 4 x 4,0 | 15,6 | 421 |

| 4 x 6,0 | 16,9 | 527 |

| 4 x 10 | 19,9 | 753 |

| 4 x 16 | 23,9 | 1100 |

| 4 x 25 | 28,1 | 1583 |

| 4 x 35 | 31,1 | 2034 |

| 4 x 50 | 36,6 | 2807 |

| 5 x 2,5 | 14,9 | 367 |

| 5 x 4,0 | 16,7 | 494 |

| 5 x 6,0 | 18,1 | 617 |

| 5 x 10 | 21,5 | 907 |

| 5 x 16 | 26,1 | 1350 |

| 5 x 25 | 30,8 | 1958 |

| 5 x 35 | 34,5 | 2545 |

| 5 x 50 | 40,0 | 3481 |

|

Number of conductors and nominal cross-section, mm2 |

Nominal outer diameter, mm |

Estimated weight of 1 km of cables, kg |

| 1 x 10 | 12,2 | 279 |

| 1 x 16 | 13,7 | 376 |

| 1 x 25 | 15,6 | 513 |

| 1 x 35 | 16,8 | 631 |

| 1 x 50 | 18,7 | 816 |

| 1 x 70 | 19,8 | 1019 |

| 1 x 95 | 21,9 | 1320 |

| 1 x 120 | 23,3 | 1570 |

| 1 x 150 | 25,6 | 1912 |

| 1 x 185 | 27,8 | 2329 |

| 1 x 240 | 30,7 | 2941 |

| 2 x 2,5 | 13,4 | 259 |

| 2 x 4,0 | 15,3 | 336 |

| 2 x 6,0 | 16,4 | 399 |

| 2 x 10 | 17,9 | 500 |

| 2 x 16 | 21,2 | 704 |

| 2 x 25 | 25,0 | 986 |

| 2 x 35 | 27,3 | 1226 |

| 2 x 50 | 31,4 | 1633 |

| 2 x 70 | 33,2 | 2030 |

| 2 x 95 | 38,2 | 2696 |

| 2 x 120 | 41,2 | 3225 |

| 2 x 150 | 45,6 | 3938 |

| 2 x 185 | 50,1 | 4815 |

| 2 x 240 | 56,3 | 6125 |

| 3 x 2,5 | 13,9 | 300 |

| 3 x 4,0 | 16,0 | 399 |

| 3 x 6,0 | 17,1 | 484 |

| 3 x 10 | 18,8 | 626 |

| 3 x 16 | 22,3 | 902 |

| 3 x 25 | 26,3 | 1288 |

| 3 x 35 | 28,8 | 1628 |

| 3 x 50 | 33,2 | 2199 |

| 3 x 70 | 35,7 | 2813 |

| 3 x 95 | 40,5 | 3718 |

| 3 x 120 | 43,6 | 4479 |

| 3 x 150 | 48,5 | 5509 |

| 3 x 185 | 53,3 | 6774 |

| 3 x 240 | 59,9 | 8655 |

| 3 x 4,0 + 1 x 2,5 | 16,6 | 444 |

| 3 x 6,0 + 1 x 4,0 | 18,3 | 550 |

| 3 x 10 + 1 x 6,0 | 20,4 | 733 |

| 3 x 16 + 1 x 10 | 23,6 | 1042 |

| 3 x 25 + 1 x 16 | 28,6 | 1512 |

| 3 x 35 + 1 x 16 | 30,6 | 1848 |

| 3 x 50 + 1 x 25 | 35,9 | 2561 |

| 3 x 70 + 1 x 35 | 37,9 | 3243 |

| 3 x 95 + 1 x 50 | 43,0 | 4314 |

| 3 x 120 + 1 x 70 | 47,0 | 5307 |

| 3 x 150 + 1 x 70 | 51,4 | 6286 |

| 3 x 185 + 1 x 95 | 57,2 | 7880 |

| 3 x 240 + 1 x 120 | 63,8 | 9968 |

| 4 x 2,5 | 15,0 | 356 |

| 4 x 4,0 | 17,1 | 471 |

| 4 x 6,0 | 18,3 | 571 |

| 4 x 10 | 20,4 | 772 |

| 4 x 16 | 24,4 | 1124 |

| 4 x 25 | 28,6 | 1610 |

| 4 x 35 | 31,6 | 2064 |

| 4 x 50 | 37,1 | 2841 |

| 4 x 70 | 39,2 | 3609 |

| 4 x 95 | 45,1 | 4835 |

| 4 x 120 | 48,6 | 5836 |

| 4 x 150 | 53,4 | 7129 |

| 4 x 185 | 58,8 | 8848 |

| 4 x 240 | 66,3 | 11273 |

| 5 x 2,5 | 16,0 | 413 |

| 5 x 4,0 | 18,3 | 547 |

| 5 x 6,0 | 19,9 | 689 |

| 5 x 10 | 22,0 | 931 |

| 5 x 16 | 26,6 | 1380 |

| 5 x 25 | 31,4 | 1992 |

| 5 x 35 | 35,1 | 2583 |

| 5 x 50 | 40,6 | 3524 |

| 5 x 70 | 43,1 | 4505 |

| 5 x 95 | 49,6 | 6048 |

| 5 x 120 | 53,5 | 7312 |

| 5 x 150 | 59,5 | 9007 |

| 5 x 185 | 65,7 | 11139 |

| 5 x 240 | 73,2 | 14189 |