KVBbSHv, KVBbSHvng, KVBbSHvngd

- KVBbSHv, KVBbSHvng, KVBbSHvngd are control armoured cables with copper conductors, PVC compound insulation, armor made of two galvanized steel bands and a PVC protective hose.

- They are designed for fixed connection to electrical devices, apparatuses, terminal block jumpers of electrical switchgear with a rated alternating voltage up to 660 V, a frequency up to 100 Hz or a constant voltage up to 1000 V.

- They are used for laying in rooms, channels, tunnels, in the ground (in trenches), including in an aggressive environment and in places exposed to leakage currents, if the cable is not subjected to significant tension strain. They can be laid outdoors, provided they are protected from mechanical damage and exposure to direct sunlight.

- 25 years when laying in rooms, tunnels, channels

operation: -50°С to +50°С

The copper conductor is not indicated on the cable marking;

K – control cable;

V – PVC insulation of conductors;

B – armor of two galvanized steel bands;

b – without bedding under armor;

SHv – PVC compound protective hose;

«ng» – does not support combustion;

«ngd» – does not support combustion, with reduced smoke and gas emission.

| Conductors: copper single-wire (class 1 DSTU EN 60228) |

| Insulation: PVC compound; sheath - PVC compound protective hose |

| Armor: two galvanized steel bands |

| Number of conductors | Nominal cross-section area of the key conductors, mm2 |

|---|---|

| 2, 3, 4, 5, 7, 10, 14, 19, 27, 37 | 0,75; 1,0; 1,5; 2,5 |

| 4, 5, 7, 10, 14, 19 | 4,0; 6,0; 10 |

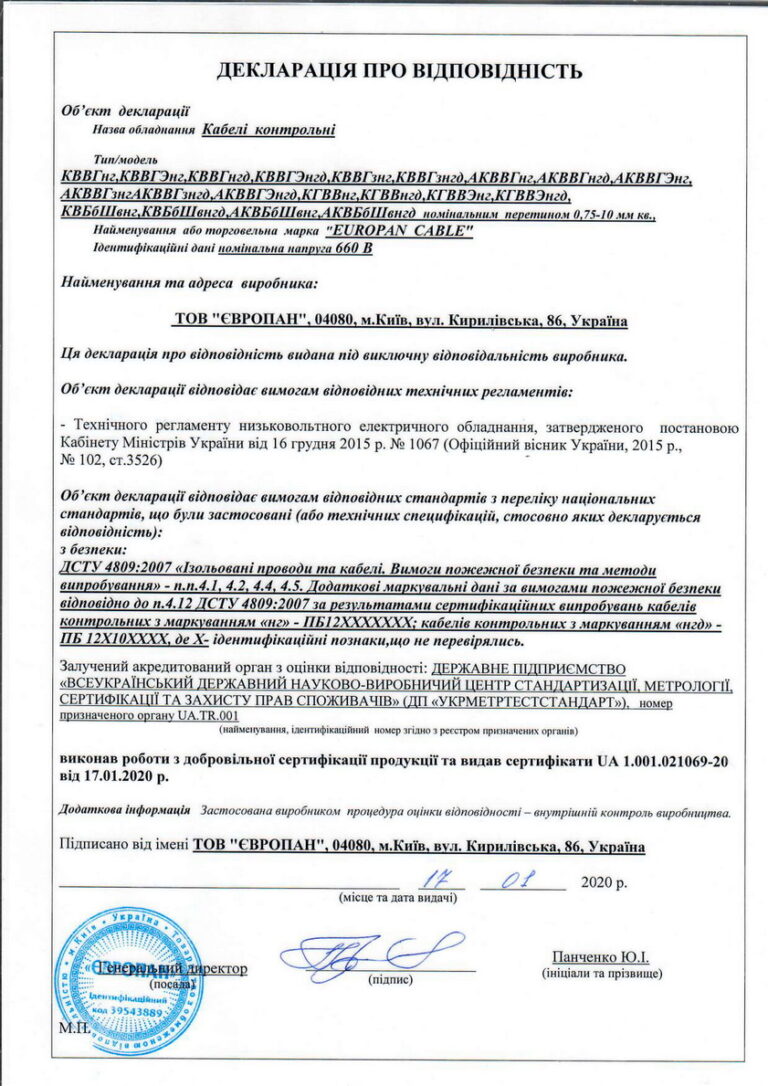

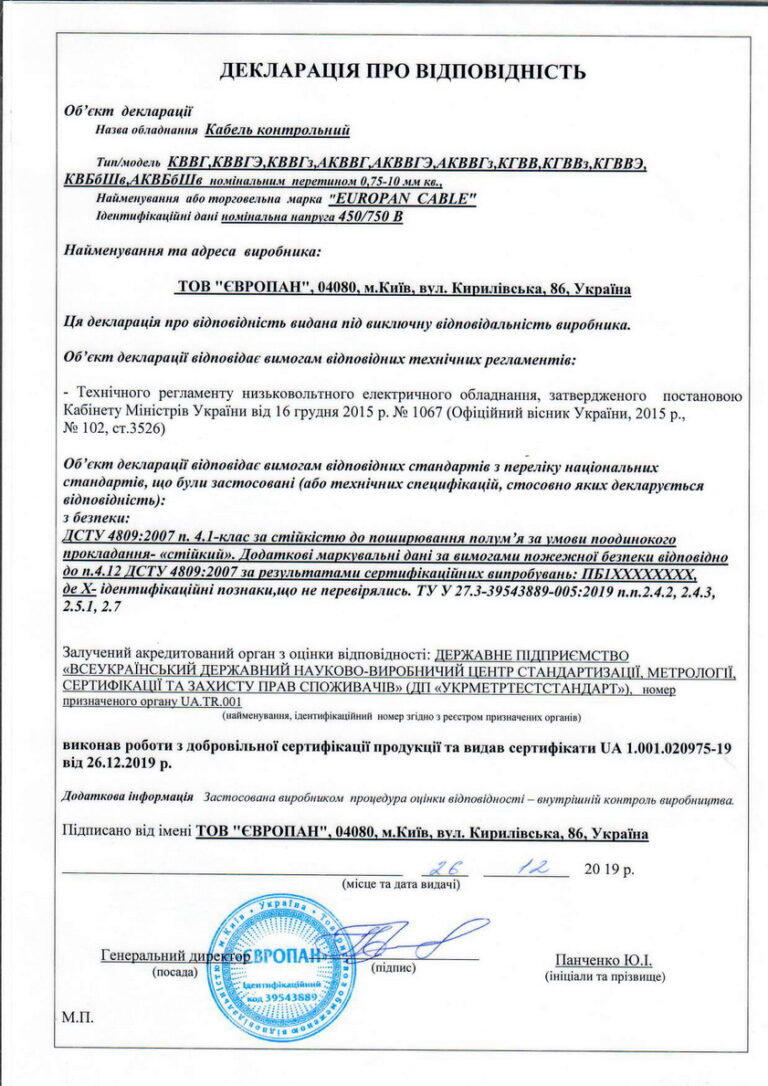

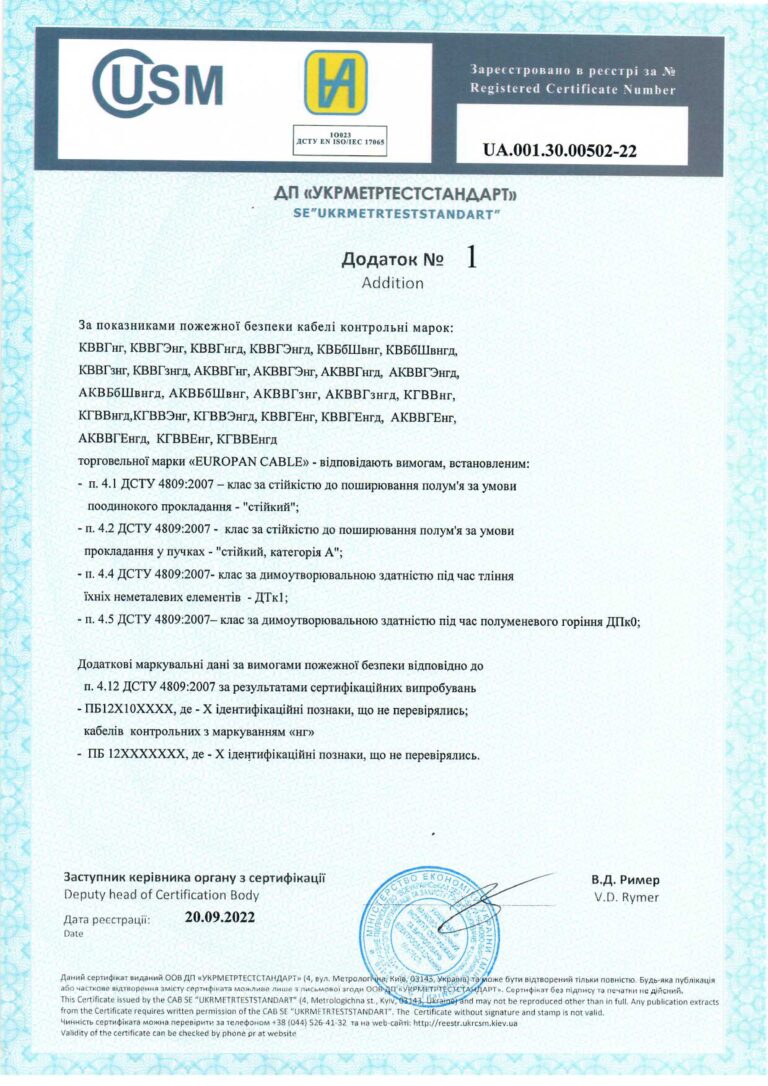

- The National Standards of Ukraine 4809:2007

- KVBbSHv - PB 1XXXXXXXX

- KVBbSHvng - PB 12XXXXXXX

- KVBbSHvngd - PB 122111XXX

KVBbSHv, KVBbSHvng, KVBbSHvngd are control armoured cables with copper conductors, PVC compound insulation, armor made of two galvanized steel bands and a PVC protective hose. The cables are used for fixed connection to electrical devices, apparatus, terminal block jumpers of electrical switchgears with a rated alternating voltage up to 660 V, a frequency up to 100 Hz or a constant voltage up to 1000 V.

Applicability scope

The main purpose of control cables is to connect individual sections of circuits located in different sections of devices or rooms.

Armoured cable KVBbSHv is used for laying in rooms, channels, tunnels, in earth trenches, including in places exposed to leakage currents, provided the cable is not subjected to significant tension strain. Such cables can be laid directly in the ground since they are armoured. And also KVBbSHv can be used in adverse conditions of an aggressive environment. The laying outdoors is allowed provided the cable is protected from the mechanical damage and exposure to direct sunlight.

The varieties of KVBbSHv of low flammability are used in places with a high probability of fire and the need to ensure the protection of people. They are marked with the letter indices «ng» and «ngd». These cables are equipped with a sheath based on non-flammable PVC compound that does not spread combustion and significantly reduce the risk of damage to cable routes and equipment in the event of a fire.

KVBbSHvng is a flame-retardant cable, and KVBbSHvngd does not spread combustion and emits the minimum possible amount of smoke and toxic gases in a fire. KVBbSHvng and KVBbSHvngd could be laid in bundles.

Design

KVBbSHv consists of a conductive single-wire copper conductor (class 1 DSTU EN 60228), with a cross section of 0.75 to 10 mm2. PVC conductors insulation has a distinctive color or digital marking. The conductors are stranded together, having an armor made of galvanized steel bands over the insulation. The upper band of the armor covers the gaps between the turns of the lower bands. A protective PVC hose covers the armor.

Operation

The control armorued cable can be used at temperatures from -50°C to +50°C and a rated air humidity up to 98% at temperatures up to +35°C. The laying without preheating is allowed at a temperature not lower than -7°C.

The bend radius during the installation must be at least 10 outer cable diameters.

Long-term permissible conductor heating temperature during operation is +70°С.

The service life of the cables is:

- at least 20 years when laying in the ground (in trenches) and on overpasses, provided that it is protected from the direct sunlight;

- at least 25 years when installed in rooms, channels and tunnels.

The guaranteed service life is 3 years.

EUROPAN LLC website presents the copper and aluminum armoured cables. They are manufactured using modern technologies and equipment and are certified in accordance with the legislation of Ukraine. Also, EUROPAN Cable Plant produces various cable and wire products, in particular, power cables, control cables, wires for overhead power lines and flexible cords are especially popular. On the website you can select and buy a conductor of the required size in accordance with your needs, get a ready-made solution based on your technical wishes and an individual support. You will also get help and advice on all issues related to the order.

Select rated voltage, kV

|

Number of conductors and nominal cross-section, mm2 |

Nominal outer diameter, mm |

Estimated weight of 1 km of cables, kg |

| 2 x 0,75 | 10,6 | 190 |

| 3 x 0,75 | 10,9 | 208 |

| 4 x 0,75 | 11,5 | 233 |

| 5 x 0,75 | 12,1 | 261 |

| 7 x 0,75 | 12,8 | 295 |

| 10 x 0,75 | 15,1 | 388 |

| 14 x 0,75 | 16,0 | 453 |

| 19 x 0,75 | 17,3 | 538 |

| 27 x 0,75 | 20,0 | 687 |

| 37 x 0,75 | 21,8 | 840 |

| 2 x 1,0 | 10,9 | 203 |

| 3 x 1,0 | 11,3 | 225 |

| 4 x 1,0 | 11,9 | 253 |

| 5 x 1,0 | 12,5 | 286 |

| 7 x 1,0 | 13,2 | 326 |

| 10 x 1,0 | 15,8 | 432 |

| 14 x 1,0 | 16,7 | 510 |

| 19 x 1,0 | 18,1 | 611 |

| 27 x 1,0 | 21,0 | 787 |

| 37 x 1,0 | 23,0 | 971 |

| 2 x 1,5 | 11,4 | 225 |

| 3 x 1,5 | 11,8 | 253 |

| 4 x 1,5 | 12,5 | 288 |

| 5 x 1,5 | 13,2 | 328 |

| 7 x 1,5 | 14,2 | 389 |

| 10 x 1,5 | 16,8 | 508 |

| 14 x 1,5 | 17,8 | 608 |

| 19 x 1,5 | 19,5 | 750 |

| 27 x 1,5 | 22,5 | 963 |

| 37 x 1,5 | 25,3 | 1242 |

| 2 x 2,5 | 12,2 | 264 |

| 3 x 2,5 | 12,7 | 304 |

| 4 x 2,5 | 13,4 | 351 |

| 5 x 2,5 | 14,5 | 414 |

| 7 x 2,5 | 15,4 | 488 |

| 10 x 2,5 | 18,4 | 647 |

| 14 x 2,5 | 19,8 | 794 |

| 19 x 2,5 | 21,5 | 981 |

| 27 x 2,5 | 25,6 | 1333 |

| 37 x 2,5 | 28,1 | 1687 |

| 4 x 4,0 | 15,2 | 462 |

| 5 x 4,0 | 16,3 | 539 |

| 7 x 4,0 | 17,4 | 648 |

| 10 x 4,0 | 21,2 | 873 |

| 14 x 4,0 | 22,7 | 1088 |

| 19 x 4,0 | 25,4 | 1403 |

| 4 x 6,0 | 16,5 | 573 |

| 5 x 6,0 | 17,7 | 677 |

| 7 x 6,0 | 19,1 | 838 |

| 10 x 6,0 | 23,3 | 1125 |

| 14 x 6,0 | 25,6 | 1465 |

| 19 x 6,0 | 28,0 | 1853 |

| 4 x 10 | 19,5 | 823 |

| 5 x 10 | 21,1 | 975 |

| 7 x 10 | 22,7 | 1213 |

| 10 x 10 | 28,6 | 1708 |

| 14 x 10 | 31,0 | 2211 |

| 19 x 10 | 34,6 | 2865 |

Select rated voltage, kV

|

Number of conductors and nominal cross-section, mm2 |

Nominal outer diameter, mm |

Estimated weight of 1 km of cables, kg |

| 2 x 0,75 | 10,6 | 194 |

| 3 x 0,75 | 10,9 | 213 |

| 4 x 0,75 | 11,5 | 238 |

| 5 x 0,75 | 12,1 | 266 |

| 7 x 0,75 | 12,8 | 301 |

| 10 x 0,75 | 15,1 | 396 |

| 14 x 0,75 | 16,0 | 461 |

| 19 x 0,75 | 17,3 | 547 |

| 27 x 0,75 | 20,0 | 698 |

| 37 x 0,75 | 21,8 | 852 |

| 2 x 1,0 | 10,9 | 208 |

| 3 x 1,0 | 11,3 | 230 |

| 4 x 1,0 | 11,9 | 258 |

| 5 x 1,0 | 12,5 | 291 |

| 7 x 1,0 | 13,2 | 333 |

| 10 x 1,0 | 15,8 | 440 |

| 14 x 1,0 | 16,7 | 518 |

| 19 x 1,0 | 18,1 | 621 |

| 27 x 1,0 | 21,0 | 799 |

| 37 x 1,0 | 23,0 | 984 |

| 2 x 1,5 | 11,4 | 230 |

| 3 x 1,5 | 11,8 | 258 |

| 4 x 1,5 | 12,5 | 294 |

| 5 x 1,5 | 13,2 | 334 |

| 7 x 1,5 | 14,2 | 396 |

| 10 x 1,5 | 16,8 | 516 |

| 14 x 1,5 | 17,8 | 618 |

| 19 x 1,5 | 19,5 | 761 |

| 27 x 1,5 | 22,5 | 976 |

| 37 x 1,5 | 25,3 | 1258 |

| 2 x 2,5 | 12,2 | 270 |

| 3 x 2,5 | 12,7 | 310 |

| 4 x 2,5 | 13,4 | 357 |

| 5 x 2,5 | 14,5 | 421 |

| 7 x 2,5 | 15,4 | 496 |

| 10 x 2,5 | 18,4 | 657 |

| 14 x 2,5 | 19,8 | 805 |

| 19 x 2,5 | 21,5 | 993 |

| 27 x 2,5 | 25,6 | 1349 |

| 37 x 2,5 | 28,1 | 1705 |

| 4 x 4,0 | 15,2 | 469 |

| 5 x 4,0 | 16,3 | 548 |

| 7 x 4,0 | 17,4 | 657 |

| 10 x 4,0 | 21,2 | 884 |

| 14 x 4,0 | 22,7 | 1101 |

| 19 x 4,0 | 25,4 | 1418 |

| 4 x 6,0 | 16,5 | 581 |

| 5 x 6,0 | 17,7 | 686 |

| 7 x 6,0 | 19,1 | 848 |

| 10 x 6,0 | 23,3 | 1138 |

| 14 x 6,0 | 25,6 | 1481 |

| 19 x 6,0 | 28,0 | 1870 |

| 4 x 10 | 19,5 | 834 |

| 5 x 10 | 21,1 | 987 |

| 7 x 10 | 22,7 | 1226 |

| 10 x 10 | 28,6 | 1726 |

| 14 x 10 | 31,0 | 2231 |

| 19 x 10 | 34,6 | 2890 |

Select rated voltage, kV

|

Number of conductors and nominal cross-section, mm2 |

Nominal outer diameter, mm |

Estimated weight of 1 km of cables, kg |

| 2 x 0,75 | 10,6 | 204 |

| 3 x 0,75 | 10,9 | 223 |

| 4 x 0,75 | 11,5 | 249 |

| 5 x 0,75 | 12,1 | 279 |

| 7 x 0,75 | 12,8 | 316 |

| 10 x 0,75 | 15,1 | 415 |

| 14 x 0,75 | 16,0 | 484 |

| 19 x 0,75 | 17,3 | 574 |

| 27 x 0,75 | 20,0 | 733 |

| 37 x 0,75 | 21,8 | 895 |

| 2 x 1,0 | 10,9 | 218 |

| 3 x 1,0 | 11,3 | 241 |

| 4 x 1,0 | 11,9 | 270 |

| 5 x 1,0 | 12,5 | 305 |

| 7 x 1,0 | 13,2 | 348 |

| 10 x 1,0 | 15,8 | 460 |

| 14 x 1,0 | 16,7 | 542 |

| 19 x 1,0 | 18,1 | 649 |

| 27 x 1,0 | 21,0 | 837 |

| 37 x 1,0 | 23,0 | 1031 |

| 2 x 1,5 | 11,4 | 241 |

| 3 x 1,5 | 11,8 | 270 |

| 4 x 1,5 | 12,5 | 307 |

| 5 x 1,5 | 13,2 | 349 |

| 7 x 1,5 | 14,2 | 413 |

| 10 x 1,5 | 16,8 | 539 |

| 14 x 1,5 | 17,8 | 644 |

| 19 x 1,5 | 19,5 | 794 |

| 27 x 1,5 | 22,5 | 1018 |

| 37 x 1,5 | 25,3 | 1313 |

| 2 x 2,5 | 12,2 | 281 |

| 3 x 2,5 | 12,7 | 323 |

| 4 x 2,5 | 13,4 | 372 |

| 5 x 2,5 | 14,5 | 439 |

| 7 x 2,5 | 15,4 | 516 |

| 10 x 2,5 | 18,4 | 682 |

| 14 x 2,5 | 19,8 | 836 |

| 19 x 2,5 | 21,5 | 1031 |

| 27 x 2,5 | 25,6 | 1401 |

| 37 x 2,5 | 28,1 | 1769 |

| 4 x 4,0 | 15,2 | 488 |

| 5 x 4,0 | 16,3 | 570 |

| 7 x 4,0 | 17,4 | 682 |

| 10 x 4,0 | 21,2 | 918 |

| 14 x 4,0 | 22,7 | 1141 |

| 19 x 4,0 | 25,4 | 1471 |

| 4 x 6,0 | 16,5 | 602 |

| 5 x 6,0 | 17,7 | 711 |

| 7 x 6,0 | 19,1 | 877 |

| 10 x 6,0 | 23,3 | 1176 |

| 14 x 6,0 | 25,6 | 1530 |

| 19 x 6,0 | 28,0 | 1930 |

| 4 x 10 | 19,5 | 863 |

| 5 x 10 | 21,1 | 1022 |

| 7 x 10 | 22,7 | 1266 |

| 10 x 10 | 28,6 | 1783 |

| 14 x 10 | 31,0 | 2303 |

| 19 x 10 | 34,6 | 2981 |