KGVVE, KGVVEng, KGVVEngd

- KGVVE, KGVVEng, KGVVEngd are flexible control cables with copper conductors, PVC insulation and sheath, and a mutual protective shield

- They are designed for fixed installation of power circuits, control circuits and local lighting on machine tools and mechanisms at voltages up to 660 V alternating current, with a frequency of 50 Hz or 1000 V direct current.

- They are used for stationary laying in places where there is a need of the conductor with increased flexibility and where the protection of electrical circuits from the influence of external electric fields is required. It is not recommended to lay cables in the ground and in open places where they can be exposed to sunlight; you should use additional ultraviolet protection in case of laying the cable outdoors.

operation: 10 x outer diameter

operation: from -50°С to +50°С

The copper conductor is not indicated on the cable marking;

K – control cable;

G – flexible;

V – PVC compound insulation of conductors;

V – PVC outer sheath;

E – protective shield;

«ng» – does not support combustion;

«ngd» – does not support combustion, with reduced smoke and gas emission.

| Conductors: copper multi-wire (class 5 DSTU EN 60228) |

| Insulation: PVC compound |

| Armor: no |

| Number of conductors | Nominal cross-section area of the key conductors, mm2 |

|---|---|

| 2, 3, 4, 5, 7, 10, 14, 19, 27, 37 | 0,75; 1,0; 1,5; 2,5 |

| 4, 5, 7, 10, 14, 19 | 4,0; 6,0; 10 |

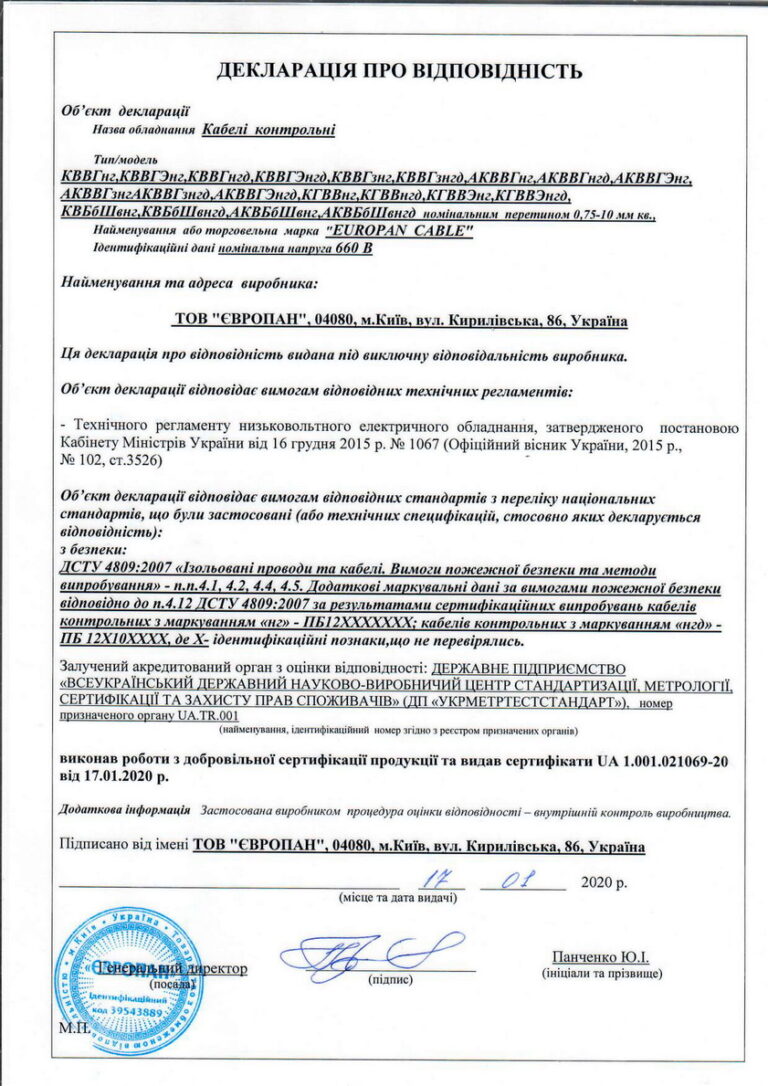

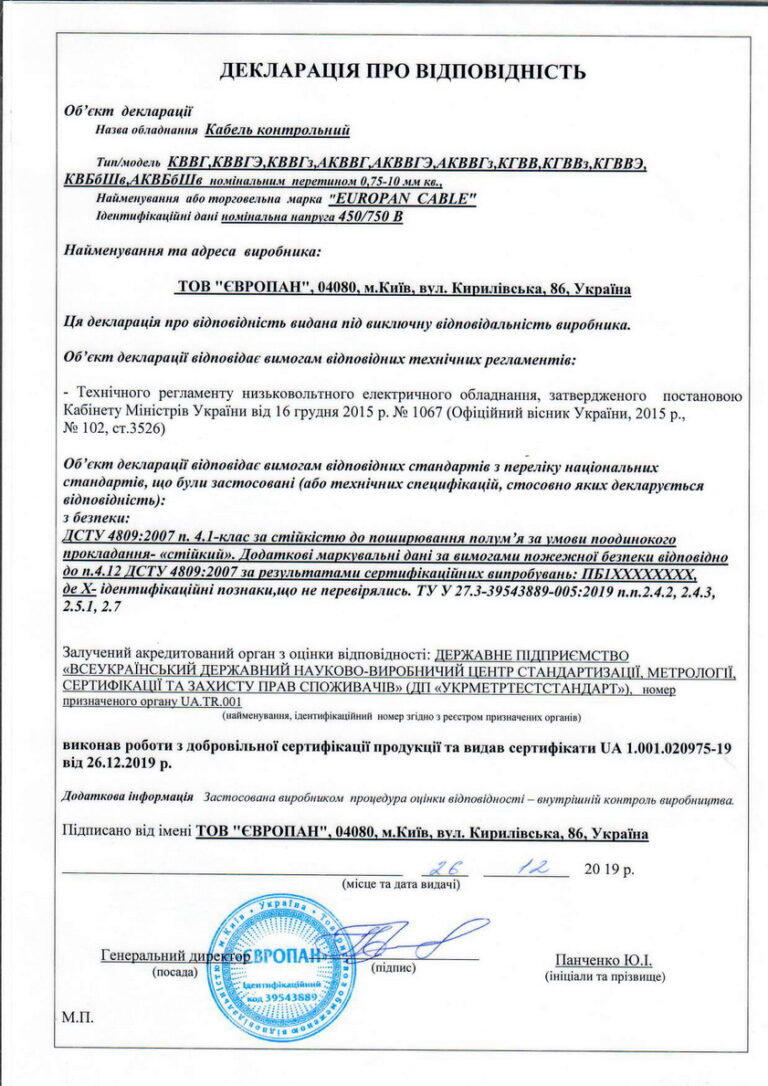

- The National Standards of Ukraine 4809:2007

- KGVVE - PB 1XXXXXXXX

- KGVVEng - PB 12XXXXXXX

- KGVVEngd - PB 122111XXX

KGVVE, KGVVEng, KGVVEngd are flexible control cables with copper conductors, PVC insulation and sheath and a mutual protective shield. They are used for fixed installation of power circuits, control circuits and local lighting on machine tools and mechanisms at a voltages up to 660 V alternating current, with a frequency of 50 Hz or 1000 V direct current.

Applicability scope

Control cables KGVVE, KGVVEng, KGVVEngd are mainly used for single stationary laying in places where there is a need of the conductor with increased flexibility. It is used for fixed installation of power circuits, control circuits of devices and mechanisms and when the protection of electrical circuits from the influence of external electric fields is required. PVC compound is sensitive to sunlight, therefore this cable brand is recommended for the indoor use. Outdoor installation is possible only with the use of ultraviolet protection measures.

It is recommended to use KGVVEng and KGVVEngd cables for bundle laying. They are made in a PVC sheath, which does not support combustion. The «ng» index indicates that the cable is flame-retardant. And the «ngd» marking indicates that the cable does not spread combustion and has a low level of smoke and gas emission in the event of a fire.

Design

The design of KGVVE essentially repeats the design of the KGVV cable, with the difference in a protective shield. It is based on a round stranded flexible conductor made of copper of the 5th flexibility class (class 5 of DSTU EN 60228). The conductors are covered with a layer of PVC compound, stranded together and color-coded. Each layer contains a marker pair of conductors, which differ in color from the rest of the conductors and from each other. In cables with up to 5 conductors, each conductor has its own individual color. Also, multi-conductors cables may consist of conductors of different cross-sections. For example, the neutral conductor and the ground conductor may have a smaller cross-section than the others. The insulated conductors are enclosed in a PVC compound sheath, and the shield is made in the form of copper or aluminum foil.

You can get more detailed information regarding the cable design, help with the selection of a conductor, as well as an additional advice from the experts of EUROPAN LLC.

Operation

KGVVE, KGVVEng, KGVVEngd can be used in various climatic parameters. The operating temperature of the cables ranges from -50°С to +50°С. The installation without preheating is carried out at a temperature not lower than -15°C. And the maximum permissible air humidity at which the cable performs its functions is 98% at a temperature of +35°C.

The maximum long-term permissible heating of conductors should not exceed +70°С.

In order to avoid damage during the installation, it is necessary to observe the permissible bend radius of the conductor, which is 7 outer cable diameters. And the minimum radius during the operation is 10 outer cable diameters.

The service life of the cables is at least 15 years. The guaranteed service life is 3 years.

On the website of EUROPAN LLC, you can purchase a flexible shielded control cable KGVVE of high quality, confirmed by certificates of conformity. Here you can buy products from stock and custom-built at the most favorable prices. And the sales managers will provide you with professional assistance in the selection of the necessary conductor, advise on any questions that arise and offer delivery at a convenient time right to the installation site.

Select rated voltage, kV

|

Number of conductors and nominal cross-section, mm2 |

Nominal outer diameter, mm |

Estimated weight of 1 km of cables, kg |

| 2 x 0,75 | 7,8 | 69 |

| 3 x 0,75 | 8,2 | 84 |

| 4 x 0,75 | 9,5 | 113 |

| 5 x 0,75 | 10,2 | 134 |

| 7 x 0,75 | 10,9 | 160 |

| 10 x 0,75 | 13,5 | 216 |

| 14 x 0,75 | 14,5 | 271 |

| 19 x 0,75 | 16,0 | 342 |

| 27 x 0,75 | 19,3 | 477 |

| 37 x 0,75 | 21,4 | 613 |

| 2 x 1,0 | 9,1 | 94 |

| 3 x 1,0 | 9,6 | 114 |

| 4 x 1,0 | 10,3 | 135 |

| 5 x 1,0 | 11,2 | 162 |

| 7 x 1,0 | 12,0 | 196 |

| 10 x 1,0 | 14,9 | 267 |

| 14 x 1,0 | 16,1 | 338 |

| 19 x 1,0 | 17,8 | 430 |

| 27 x 1,0 | 21,5 | 601 |

| 37 x 1,0 | 24,3 | 801 |

| 2 x 1,5 | 9,9 | 112 |

| 3 x 1,5 | 10,4 | 137 |

| 4 x 1,5 | 11,2 | 165 |

| 5 x 1,5 | 12,2 | 199 |

| 7 x 1,5 | 13,2 | 243 |

| 10 x 1,5 | 16,4 | 333 |

| 14 x 1,5 | 17,8 | 428 |

| 19 x 1,5 | 20,1 | 566 |

| 27 x 1,5 | 24,2 | 790 |

| 37 x 1,5 | 27,0 | 1026 |

| 2 x 2,5 | 10,8 | 139 |

| 3 x 2,5 | 11,4 | 174 |

| 4 x 2,5 | 12,3 | 213 |

| 5 x 2,5 | 13,4 | 260 |

| 7 x 2,5 | 14,5 | 323 |

| 10 x 2,5 | 18,6 | 463 |

| 14 x 2,5 | 20,2 | 600 |

| 19 x 2,5 | 22,4 | 773 |

| 27 x 2,5 | 27,0 | 1083 |

| 37 x 2,5 | 30,2 | 1421 |

| 4 x 4,0 | 14,3 | 296 |

| 5 x 4,0 | 15,6 | 365 |

| 7 x 4,0 | 17,0 | 460 |

| 10 x 4,0 | 21,9 | 660 |

| 14 x 4,0 | 24,2 | 888 |

| 19 x 4,0 | 26,8 | 1151 |

| 4 x 6,0 | 16,7 | 401 |

| 5 x 6,0 | 18,7 | 516 |

| 7 x 6,0 | 20,3 | 652 |

| 10 x 6,0 | 26,2 | 933 |

| 14 x 6,0 | 28,5 | 1229 |

| 19 x 6,0 | 31,7 | 1604 |

| 4 x 10 | 20,2 | 618 |

| 5 x 10 | 22,2 | 773 |

| 7 x 10 | 24,6 | 1012 |

| 10 x 10 | 31,4 | 1416 |

| 14 x 10 | 34,6 | 1922 |

| 19 x 10 | 38,7 | 2523 |

Select rated voltage, kV

|

Number of conductors and nominal cross-section, mm2 |

Nominal outer diameter, mm |

Estimated weight of 1 km of cables, kg |

| 2 x 0,75 | 7,8 | 71 |

| 3 x 0,75 | 8,2 | 86 |

| 4 x 0,75 | 9,5 | 115 |

| 5 x 0,75 | 10,2 | 137 |

| 7 x 0,75 | 10,9 | 163 |

| 10 x 0,75 | 13,5 | 220 |

| 14 x 0,75 | 14,5 | 276 |

| 19 x 0,75 | 16,0 | 347 |

| 27 x 0,75 | 19,3 | 484 |

| 37 x 0,75 | 21,4 | 621 |

| 2 x 1,0 | 9,1 | 97 |

| 3 x 1,0 | 9,6 | 116 |

| 4 x 1,0 | 10,3 | 138 |

| 5 x 1,0 | 11,2 | 166 |

| 7 x 1,0 | 12,0 | 200 |

| 10 x 1,0 | 14,9 | 271 |

| 14 x 1,0 | 16,1 | 343 |

| 19 x 1,0 | 17,8 | 435 |

| 27 x 1,0 | 21,5 | 609 |

| 37 x 1,0 | 24,3 | 811 |

| 2 x 1,5 | 9,9 | 115 |

| 3 x 1,5 | 10,4 | 140 |

| 4 x 1,5 | 11,2 | 168 |

| 5 x 1,5 | 12,2 | 203 |

| 7 x 1,5 | 13,2 | 247 |

| 10 x 1,5 | 16,4 | 338 |

| 14 x 1,5 | 17,8 | 433 |

| 19 x 1,5 | 20,1 | 573 |

| 27 x 1,5 | 24,2 | 800 |

| 37 x 1,5 | 27,0 | 1037 |

| 2 x 2,5 | 10,8 | 142 |

| 3 x 2,5 | 11,4 | 178 |

| 4 x 2,5 | 12,3 | 217 |

| 5 x 2,5 | 13,4 | 264 |

| 7 x 2,5 | 14,5 | 328 |

| 10 x 2,5 | 18,6 | 470 |

| 14 x 2,5 | 20,2 | 607 |

| 19 x 2,5 | 22,4 | 781 |

| 27 x 2,5 | 27,0 | 1094 |

| 37 x 2,5 | 30,2 | 1433 |

| 4 x 4,0 | 14,3 | 300 |

| 5 x 4,0 | 15,6 | 370 |

| 7 x 4,0 | 17,0 | 465 |

| 10 x 4,0 | 21,9 | 667 |

| 14 x 4,0 | 24,2 | 897 |

| 19 x 4,0 | 26,8 | 1161 |

| 4 x 6,0 | 16,7 | 406 |

| 5 x 6,0 | 18,7 | 523 |

| 7 x 6,0 | 20,3 | 659 |

| 10 x 6,0 | 26,2 | 943 |

| 14 x 6,0 | 28,5 | 1241 |

| 19 x 6,0 | 31,7 | 1617 |

| 4 x 10 | 20,2 | 625 |

| 5 x 10 | 22,2 | 781 |

| 7 x 10 | 24,6 | 1022 |

| 10 x 10 | 31,4 | 1429 |

| 14 x 10 | 34,6 | 1937 |

| 19 x 10 | 38,7 | 2540 |

Select rated voltage, kV

|

Number of conductors and nominal cross-section, mm2 |

Nominal outer diameter, mm |

Estimated weight of 1 km of cables, kg |

| 2 x 0,75 | 7,8 | 76 |

| 3 x 0,75 | 8,2 | 91 |

| 4 x 0,75 | 9,5 | 123 |

| 5 x 0,75 | 10,2 | 147 |

| 7 x 0,75 | 10,9 | 174 |

| 10 x 0,75 | 13,5 | 235 |

| 14 x 0,75 | 14,5 | 295 |

| 19 x 0,75 | 16,0 | 371 |

| 27 x 0,75 | 19,3 | 517 |

| 37 x 0,75 | 21,4 | 664 |

| 2 x 1,0 | 9,1 | 104 |

| 3 x 1,0 | 9,6 | 124 |

| 4 x 1,0 | 10,3 | 148 |

| 5 x 1,0 | 11,2 | 177 |

| 7 x 1,0 | 12,0 | 213 |

| 10 x 1,0 | 14,9 | 290 |

| 14 x 1,0 | 16,1 | 367 |

| 19 x 1,0 | 17,8 | 465 |

| 27 x 1,0 | 21,5 | 650 |

| 37 x 1,0 | 24,3 | 866 |

| 2 x 1,5 | 9,9 | 122 |

| 3 x 1,5 | 10,4 | 149 |

| 4 x 1,5 | 11,2 | 179 |

| 5 x 1,5 | 12,2 | 216 |

| 7 x 1,5 | 13,2 | 263 |

| 10 x 1,5 | 16,4 | 359 |

| 14 x 1,5 | 17,8 | 460 |

| 19 x 1,5 | 20,1 | 609 |

| 27 x 1,5 | 24,2 | 850 |

| 37 x 1,5 | 27,0 | 1102 |

| 2 x 2,5 | 10,8 | 151 |

| 3 x 2,5 | 11,4 | 188 |

| 4 x 2,5 | 12,3 | 229 |

| 5 x 2,5 | 13,4 | 280 |

| 7 x 2,5 | 14,5 | 345 |

| 10 x 2,5 | 18,6 | 496 |

| 14 x 2,5 | 20,2 | 640 |

| 19 x 2,5 | 22,4 | 823 |

| 27 x 2,5 | 27,0 | 1152 |

| 37 x 2,5 | 30,2 | 1508 |

| 4 x 4,0 | 14,3 | 316 |

| 5 x 4,0 | 15,6 | 390 |

| 7 x 4,0 | 17,0 | 488 |

| 10 x 4,0 | 21,9 | 701 |

| 14 x 4,0 | 24,2 | 943 |

| 19 x 4,0 | 26,8 | 1219 |

| 4 x 6,0 | 16,7 | 426 |

| 5 x 6,0 | 18,7 | 551 |

| 7 x 6,0 | 20,3 | 691 |

| 10 x 6,0 | 26,2 | 989 |

| 14 x 6,0 | 28,5 | 1299 |

| 19 x 6,0 | 31,7 | 1691 |

| 4 x 10 | 20,2 | 654 |

| 5 x 10 | 22,2 | 820 |

| 7 x 10 | 24,6 | 1068 |

| 10 x 10 | 31,4 | 1493 |

| 14 x 10 | 34,6 | 2023 |

| 19 x 10 | 38,7 | 2651 |