AKVVGE, AKVVGEng, AKVVGEngd

- AKVVGE, AKVVGEng, AKVVGEngd are control cables with aluminum conductors, PVC compound insulation, PVC sheath, and protective shield.

- They are designed for the stationary connection to electrical devices, apparatuses, terminal block jumpers of electrical switchgear with a rated alternating voltage up to 660 V, a frequency up to 100 Hz or constant voltage up to 1000 V.

- They are used for laying in rooms, channels, tunnels, if there is no mechanical stress on the cable in an aggressive environment and there is no need to protect electrical circuits from the influence of external electric fields. They can be laid outdoors, provided they are protected from mechanical damage and exposure to direct sunlight.

- 25 years when laying in rooms, tunnels, channels

operation: from -50°С to +50°С

A – aluminum conductor;

K – control cable;

V – PVC compound insulation;

V – PVC outer sheath;

G – without armor («bare»);

E – shielded;

«ng» – does not support combustion;

«ngd» – does not support combustion, with reduced smoke and gas emission.

| Conductors: aluminum single-wire (class 1 DSTU EN 60228) |

| Insulation: PVC compound |

| Armor: no |

| Number of conductors | Nominal cross-section area of the key conductors, mm2 |

|---|---|

| 4, 5, 7, 10, 14, 19, 27, 37 | 2,5 |

| 4, 5, 7, 10, 14, 19 | 4,0; 6,0; 10 |

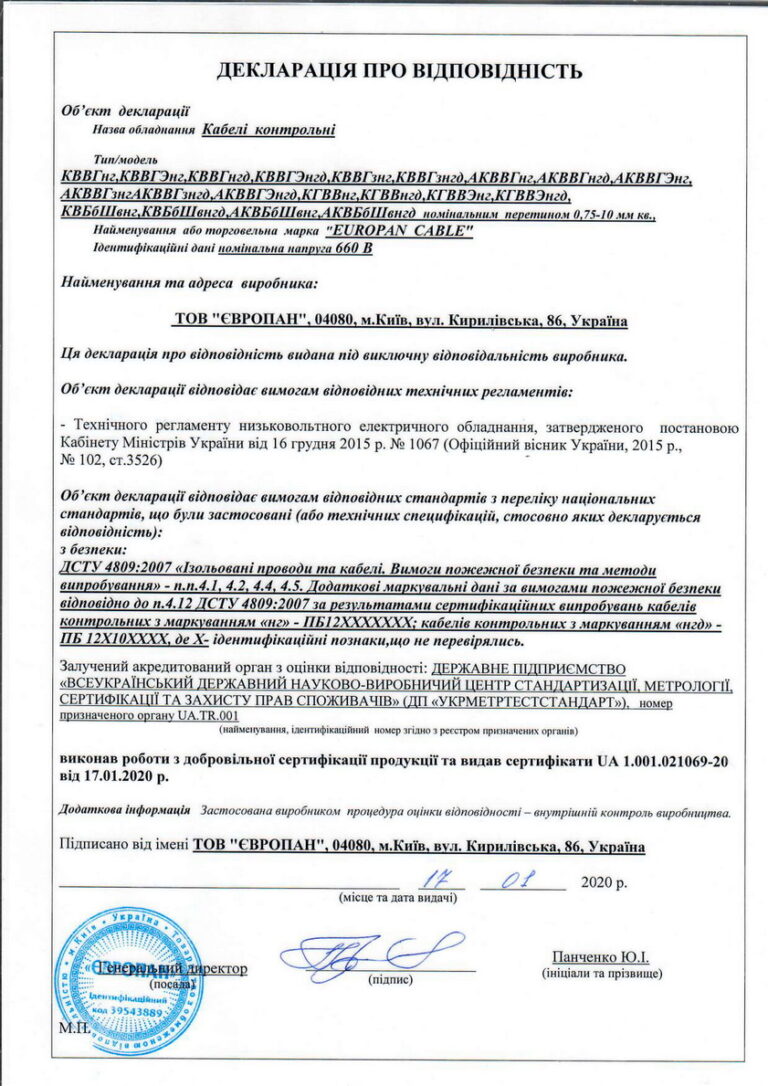

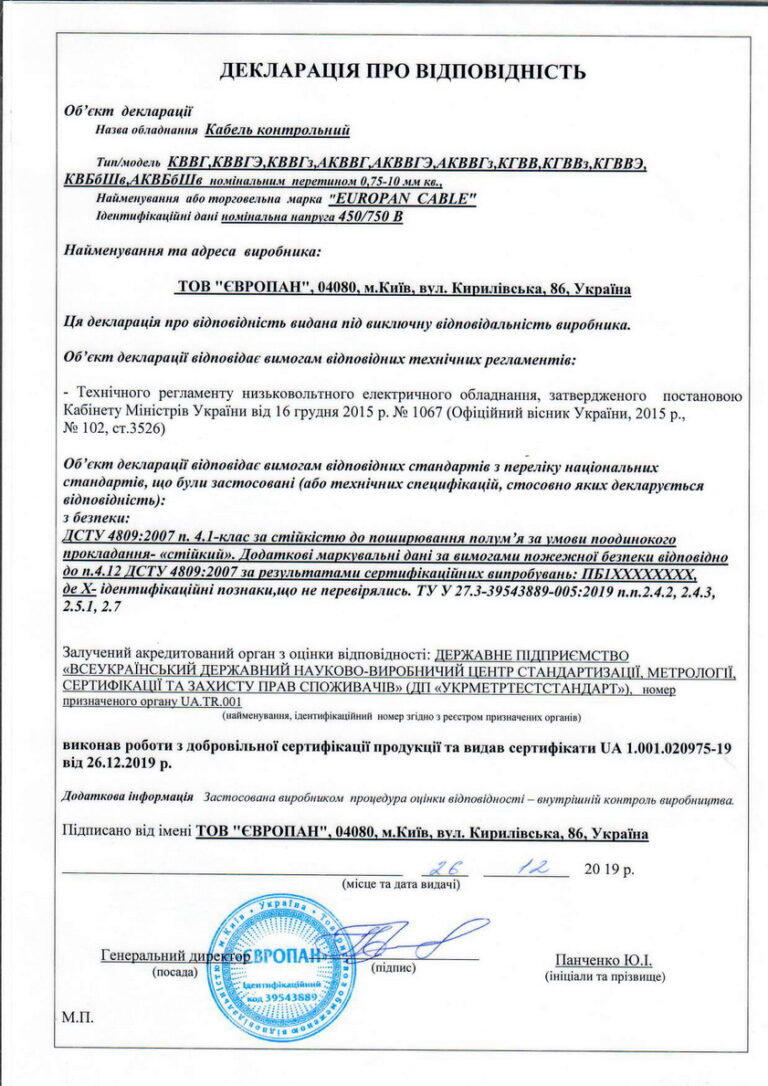

- The National Standards of Ukraine 4809:2007

- ВВГ-П – ПБ 1ХХХХХХХХ

- ВВГ-Пнг – ПБ 12ХХХХХХХ

- ВВГ-Пнгд – ПБ 122111ХХХ

AKVVGE, AKVVGEng, AKVVGEngd are control cables with aluminum conductors, PVC compound insulation, PVC sheath and protective shield. They are designed for the stationary connection to electrical devices, apparatuses, terminal block jumpers of electrical switchgear with a rated alternating voltage up to 660 V and a frequency up to 100 Hz or a constant voltage up to 1000 V.

Applicability scope

Shielded cables AKVVGE, AKVVGEng, AKVVGEngd are used in places where it is necessary to protect electrical circuits from the influence of external electric fields. They are used in rooms, channels, tunnels, in an aggressive environment provided there is no mechanical stress on the cable. In addition, they could be laid outdoors, subject to protection from mechanical damage and exposure to direct sunlight.

AKVVGE is used mainly for single laying in cable structures and rooms. Thegroup laying is allowed only in outdoor electrical installations and industrial premises using additional passive fire protection equipment.

The type of AKVVGE with the letter index «ng» indicates that this cable does not spread combustion. And the index «ngd» indicates that the cable does not support combustion and has a low level of smoke emission in the event of a fire. AKVVGEng and AKVVGEngd are commonly used in places with an increased likelihood of fire and increased requirements for fire safety. And also they can be used for the group laying.

Design

The AKVVGE design consists of several insulated aluminum single-wire conductors of the 1st flexibility class (class 1 of DSTU EN 60228). Each conductor is covered with a layer of PVC compound. The conductors are stranded together and are color-coded or numerically coded. The inner and outer sheaths of the cable are also made of PVC material. And the protective shield can be made of copper or aluminum foil.

Experts of EUROPAN LLC will provide you with more detailed information about the cable design, help in selecting a conductor taking into account the load power, as well as give an additional advice.

Operation

AKVVGE cables are designed for operation at temperatures from -50°C to +50°C. The maximum permissible air humidity is 98% at a temperature of +35°C. The installation of cables without preheating is permissible at a temperature not lower than -15°С.

The minimum bend radius during installation must be at least 6 outer cable diameters.

The long-term permissible conductor heating temperature during operation is +70°C.

Conductor’s service life is as follows:

- at least 20 years – when laying in earth trenches and on overpasses, provided they are protected from ultraviolet radiation;

- at least 25 years – when laying in rooms, tunnels, channels.

The guaranteed service life is 3 years.

The website of EUROPAN LLC presents a shielded control cable AKVVGE of various label sizes, as well as power cables of various nomenclature. All our products are certified in accordance with the Ukrainian legislation and meet high safety requirements. As a manufacturer, we offer you the best quality-to-price ratio. And our managers will select the most optimal solution for your technical requirements.

Select rated voltage, kV

|

Number of conductors and nominal cross-section, mm2 |

Nominal outer diameter, mm |

Estimated weight of 1 km of cables, kg |

| 4 x 2,5 | 10,6 | 128 |

| 5 x 2,5 | 11,4 | 154 |

| 7 x 2,5 | 12,3 | 182 |

| 10 x 2,5 | 15,3 | 247 |

| 14 x 2,5 | 16,5 | 310 |

| 19 x 2,5 | 18,7 | 408 |

| 27 x 2,5 | 22,1 | 545 |

| 37 x 2,5 | 25,1 | 723 |

| 4 x 4,0 | 12,2 | 169 |

| 5 x 4,0 | 13,2 | 205 |

| 7 x 4,0 | 14,3 | 247 |

| 10 x 4,0 | 18,0 | 337 |

| 14 x 4,0 | 19,8 | 448 |

| 19 x 4,0 | 22,0 | 567 |

| 4 x 6,0 | 13,4 | 208 |

| 5 x 6,0 | 14,6 | 255 |

| 7 x 6,0 | 15,9 | 311 |

| 10 x 6,0 | 20,4 | 446 |

| 14 x 6,0 | 22,1 | 571 |

| 19 x 6,0 | 25,0 | 752 |

| 4 x 10 | 16,3 | 304 |

| 5 x 10 | 17,8 | 378 |

| 7 x 10 | 19,8 | 483 |

| 10 x 10 | 25,6 | 692 |

| 14 x 10 | 27,8 | 894 |

| 19 x 10 | 30,9 | 1151 |

Select rated voltage, kV

|

Number of conductors and nominal cross-section, mm2 |

Nominal outer diameter, mm |

Estimated weight of 1 km of cables, kg |

| 4 x 2,5 | 10,6 | 131 |

| 5 x 2,5 | 11,4 | 157 |

| 7 x 2,5 | 12,3 | 186 |

| 10 x 2,5 | 15,3 | 252 |

| 14 x 2,5 | 16,5 | 315 |

| 19 x 2,5 | 18,7 | 414 |

| 27 x 2,5 | 22,1 | 553 |

| 37 x 2,5 | 25,1 | 733 |

| 4 x 4,0 | 12,2 | 172 |

| 5 x 4,0 | 13,2 | 209 |

| 7 x 4,0 | 14,3 | 251 |

| 10 x 4,0 | 18,0 | 343 |

| 14 x 4,0 | 19,8 | 455 |

| 19 x 4,0 | 22,0 | 575 |

| 4 x 6,0 | 13,4 | 212 |

| 5 x 6,0 | 14,6 | 260 |

| 7 x 6,0 | 15,9 | 315 |

| 10 x 6,0 | 20,4 | 453 |

| 14 x 6,0 | 22,1 | 579 |

| 19 x 6,0 | 25,0 | 762 |

| 4 x 10 | 16,3 | 309 |

| 5 x 10 | 17,8 | 383 |

| 7 x 10 | 19,8 | 490 |

| 10 x 10 | 25,6 | 702 |

| 14 x 10 | 27,8 | 905 |

| 19 x 10 | 30,9 | 1163 |

Select rated voltage, kV

|

Number of conductors and nominal cross-section, mm2 |

Nominal outer diameter, mm |

Estimated weight of 1 km of cables, kg |

| 4 x 2,5 | 10,6 | 140 |

| 5 x 2,5 | 11,4 | 168 |

| 7 x 2,5 | 12,3 | 199 |

| 10 x 2,5 | 15,3 | 269 |

| 14 x 2,5 | 16,5 | 337 |

| 19 x 2,5 | 18,7 | 443 |

| 27 x 2,5 | 22,1 | 591 |

| 37 x 2,5 | 25,1 | 784 |

| 4 x 4,0 | 12,2 | 184 |

| 5 x 4,0 | 13,2 | 224 |

| 7 x 4,0 | 14,3 | 268 |

| 10 x 4,0 | 18,0 | 366 |

| 14 x 4,0 | 19,8 | 485 |

| 19 x 4,0 | 22,0 | 614 |

| 4 x 6,0 | 13,4 | 226 |

| 5 x 6,0 | 14,6 | 277 |

| 7 x 6,0 | 15,9 | 335 |

| 10 x 6,0 | 20,4 | 482 |

| 14 x 6,0 | 22,1 | 614 |

| 19 x 6,0 | 25,0 | 809 |

| 4 x 10 | 16,3 | 328 |

| 5 x 10 | 17,8 | 408 |

| 7 x 10 | 19,8 | 521 |

| 10 x 10 | 25,6 | 746 |

| 14 x 10 | 27,8 | 961 |

| 19 x 10 | 30,9 | 1234 |